The oil and gas industry is among the most complex and hazardous sectors worldwide, where operational challenges intersect with the risks of fires and explosions that can have devastating consequences. In addressing these dangers, fire suppression systems serve as an indispensable first line of defense, protecting lives and assets while ensuring the continuity of industrial operations.

These systems rely on an integrated structure that includes advanced detectors capable of identifying even the slightest indicators of danger, intelligent control panels that process data within fractions of a second, and specialized suppression agents tailored to the specific nature of each type of fire. All components work in precise harmony—from the moment of detection, through analysis and decision-making, to the immediate execution of suppression.

This article aims to provide a comprehensive overview of fire suppression systems in the oil and gas sector by examining their core components, modes of operation, key standards, and the emerging trends that will shape the future of industrial safety in the years ahead.

Table of Contents

What Is a Fire Suppression System in the Oil and Gas Industry?

A fire suppression system in the oil and gas sector is an ultra-high-speed, automated safety system engineered to detect and suppress incipient combustion or explosive reactions within milliseconds to seconds, preventing escalation into full-scale fires or catastrophic explosions.

These systems function by disrupting the fire tetrahedron (heat, fuel, oxygen, and chemical chain reaction) through the rapid discharge of specialized extinguishing agents. They are primarily categorized into two main types:

- Fire Suppression Systems – Used in enclosed areas such as control rooms to isolate oxygen or reduce heat. Common agents include clean agents (Novec 1230, HFC-227ea) or carbon dioxide (CO₂).

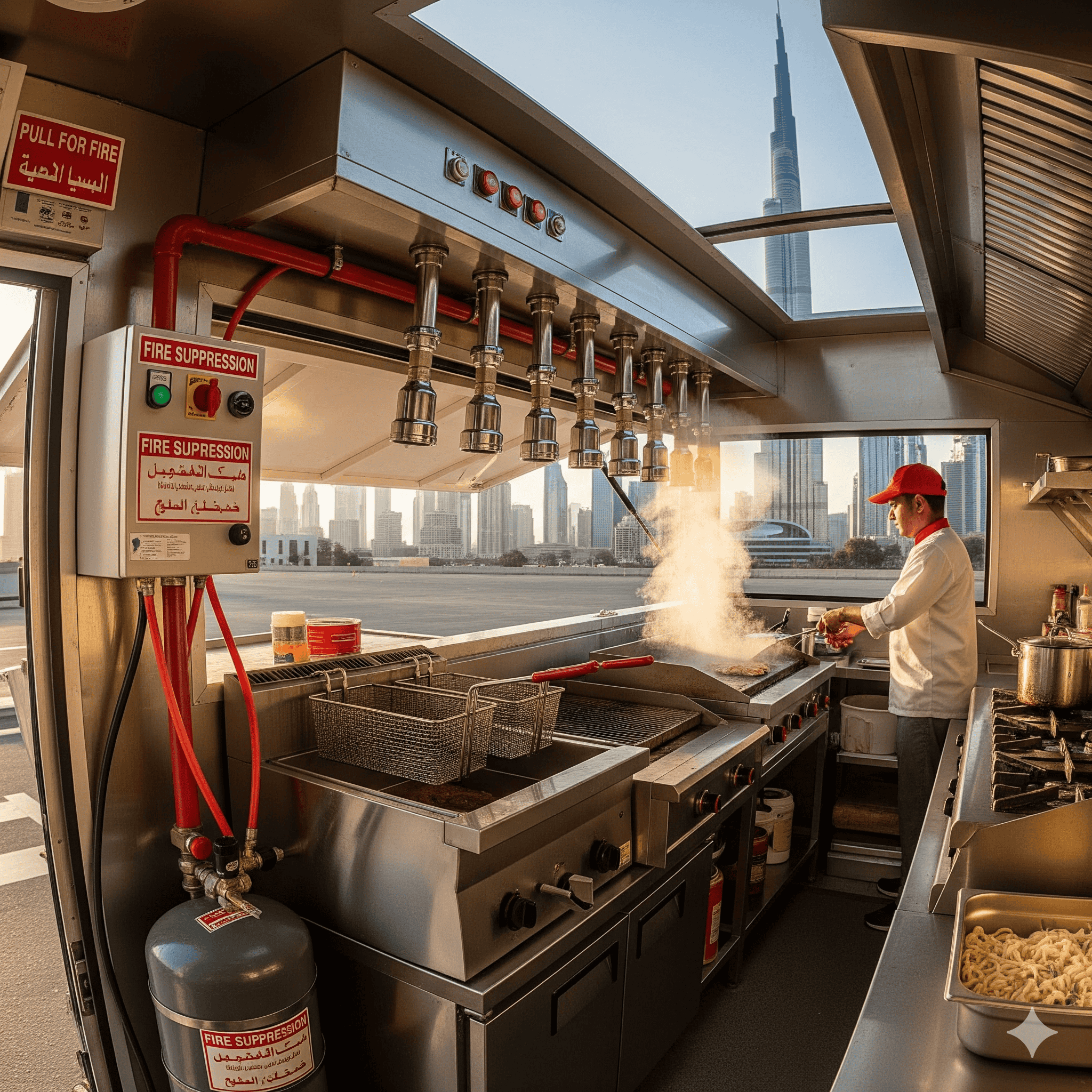

- Explosion Suppression Systems – Designed for high-risk zones such as silos, filters, or processing units. They detect the initial pressure wave of an explosion and instantly discharge dry chemical agents (e.g., sodium bicarbonate) to quench the reaction before explosive energy builds up.

As the first line of defense, suppression systems are critical for protecting lives, vital equipment, and infrastructure in oil and gas facilities.

Core Components of Fire Suppression Systems in the Oil and Gas Industry

The main components of a fire suppression system in the oil and gas Industry begin with detection devices that identify the earliest signs of fire, while the control panel processes the signals, makes activation decisions, and triggers alarms and cylinders.

Then, the appropriate suppression agent—such as clean agents, CO₂, foam, or dry chemical powders—is released, along with the distribution network, manual alarms, and finally, automatic shutdown interfaces.

All components are specifically designed to withstand the harsh and hazardous environments of the petroleum industry, as detailed below:

1. Detection Devices: Detect the earliest signs of fire and are classified into:

Smoke Detectors: Capture particles produced during combustion.

Flame Detectors: Detect optical radiation (ultraviolet UV or infrared IR) emitted by flames. Essential for open or outdoor areas in oil facilities.

Heat Detectors: Respond to abnormal temperature increases, either fixed or rate-of-rise.

2. Control Panel: The system’s brain, responsible for:

Receiving signals from detection devices.

Processing data and making activation decisions.

Triggering audible and visual alarms (sirens and strobe lights).

Sending electrical signals to activate suppression agent cylinders.

Monitoring system status and displaying faults.

3. Suppression Agent Cylinders: High-pressure tanks containing the extinguishing agent, electrically activated by the control panel.

4. Suppression Agent: The material released to extinguish the fire, selected according to the hazard type:

Clean Agents: Such as Novec 1230, ideal for control rooms and electronic equipment because they are non-conductive and leave no residue.

Carbon Dioxide (CO₂): Highly effective but hazardous to humans in confined spaces, typically used in unmanned areas like engine rooms or oil pumping stations.

Foam: Primarily used for flammable liquid (hydrocarbon) fires in storage areas, containment pits, and pumping stations.

Dry Chemical Powder: Such as sodium bicarbonate, used for fires involving flammable liquids and gases.

5. Distribution Network:

Piping: Transfers the suppression agent from cylinders to the hazard area.

Nozzles / Discharge Horns: Designed to deliver the agent efficiently and evenly. Their design varies depending on the type of agent used (gas, foam, or powder).

6. Alarm and Notification Devices:

Sirens or alarm bells.

Strobe lights.

Warning signs, e.g., “Agent Release Imminent – Evacuate Immediately.”

7. Manual Activation Devices:

Manual Call Points: Allow personnel to activate the system manually in emergencies.

Manual Pull Stations: Installed near emergency exits or close to the hazard area.

8. Automatic Shutdown Interfaces:

Connections to cut electrical power to the protected area upon activation.

Links to shut off fuel or gas supply valves to prevent feeding the fire.

By integrating all these components, fire suppression systems in UAE oil and gas facilities provide fast detection, immediate suppression, and protection of lives, critical equipment, and infrastructure. This makes them a central part of comprehensive fire protection strategies implemented by fire suppression system companies in UAE.

How Does a Fire Suppression System Work in the Oil and Gas Sector?

An industrial fire suppression system in oil and gas facilities operates by first detecting fire through specialized sensors, such as flame, smoke, and heat detectors, which monitor hazards in their earliest stages. The control panel then processes the signals, activates warning alarms, and automatically isolates energy and fuel sources.

Next, suppression agent cylinders release specialized extinguishing materials—such as clean agents or foam—through a network of engineered piping and discharge nozzles. Finally, these agents suppress the fire through multiple mechanisms, including oxygen deprivation, heat reduction, and interruption of the chemical reaction chain to prevent re-ignition.

Why Do Industrial Fire Suppression Systems Differ from Conventional Systems?

Industrial fire protection solutions for oil and gas facilities differ significantly from conventional systems due to the unique hazards they address. These systems manage flammable liquids and gases under high pressure and extreme temperatures (Class B), as well as electrical fires (Class C), whereas traditional systems are designed for ordinary fires involving solid materials (Class A).

Unlike conventional sprinklers or standard fire extinguishers, these specialized fire suppression systems in UAE oil and gas facilities rely on high-expansion foams, inert gases, or dry chemical agents (clean agents) instead of water, which is often ineffective and unsafe in such environments. They suppress fires by smothering flames with foam, reducing oxygen levels below the ignition threshold, or interrupting the chemical reaction chain to prevent escalation and minimize damage to sensitive equipment.

Additionally, commercial fire suppression solutions integrate with critical safety mechanisms, such as emergency shutdown systems (ESD) and industrial ventilation, ensuring maximum operational reliability in classified hazardous areas. They feature explosion-proof designs and comply with international standards like API, NFPA, IECEx, and ATEX, whereas conventional systems follow general building codes such as NFPA Life Safety Code.

| Feature | Oil & Gas Fire Suppression System | Conventional Fire System |

|---|---|---|

| Hazard Type | Flammable gases and liquids under high pressure | Ordinary solid and liquid fires |

| Suppression Agents | Specialized foams, dry chemical agents, clean agents | Water, general-purpose chemical powders |

| Design Environment | Hazardous areas | Normal environments (offices, residences) |

| Standards | API, NFPA, IECEx, ATEX | NFPA, local building codes |

| Response Time | Fractions of a second to a few seconds | Seconds to minutes |

| Cost | Very high | Medium to low |

These distinctions demonstrate why fire suppression system companies in the UAE are critical for designing, installing, and maintaining fire suppression solutions that ensure safety and compliance with both local and international regulations.

The Importance of Fire Protection in the Oil and Gas Industry

The importance of Fire protection systems for the petroleum industry lies first and foremost in protecting human lives by minimizing the risk of fires and explosions and providing safe evacuation time. Beyond life safety, these systems safeguard assets, infrastructure, and business continuity, while also ensuring environmental protection and regulatory compliance.

Key aspects of fire protection importance include:

- Human Safety: Fires and explosions pose severe risks to workers and surrounding communities. Advanced fire protection systems aim to prevent incidents altogether, or if they occur, suppress them immediately to allow safe evacuation.

- Asset Protection: Oil and gas facilities represent massive investments—offshore platforms, refineries, and processing plants. Fires can destroy equipment worth millions or even billions of dollars and cripple critical infrastructure.

- Business Continuity: Any unplanned shutdown due to fire results in heavy production and revenue losses.

- Environmental Protection: Fires and explosions can trigger catastrophic environmental disasters, such as crude oil spills contaminating soil, groundwater, and oceans, with long-term impacts on marine and terrestrial ecosystems.

- Reputation & Social Responsibility: Major incidents damage corporate reputation, credibility, and stakeholder trust, while undermining relationships with local communities.

- Regulatory Compliance: The oil and gas sector is governed by strict local and international standards (e.g., OSHA, NFPA, API). Effective fire protection is not optional but a legal requirement to operate facilities, avoid fines, and prevent shutdowns.

By addressing these dimensions, fire suppression systems play a critical role in ensuring safety, sustainability, and resilience in the oil and gas industry.

Early Detection and Alarm Systems in the Oil and Gas Industry: The First Line of Defense

In the oil and gas sector, early detection and alarm systems serve as the primary defense line against fires and explosions, identifying hazards at their initial stages before they escalate into catastrophic events.

These systems incorporate gas detectors to monitor leaks, smoke detectors to identify combustion particles, heat detectors to sense abrupt temperature changes, and flame detectors utilizing infrared or ultraviolet radiation sensing.

All detectors are integrated with a central control panel that instantly analyzes data and triggers distinct audible and visual alarms. Simultaneously, the system can initiate automated protocols—such as equipment isolation, emergency ventilation activation, or suppression system deployment—ensuring comprehensive protection of lives and assets in high-risk oil and gas environments.

Primary Types of Detection Systems Used:

- Gas Detectors

- Flame Detectors

- Smoke Detectors

- Heat Detectors

Gas Detectors: The Life-Saving Technology Protecting Lives and Billions

Gas detectors are indispensable safety devices engineered to identify flammable gases (e.g., Methane CH₄), toxic gases (such as H₂S and CO), and oxygen deficiency or enrichment (O₂ levels outside the safe range of 19.5% – 23.5%).

These devices employ advanced technologies—including catalytic sensors, infrared (IR) absorption, and electrochemical sensors—to deliver high precision and rapid response in hazardous environments.

Types of Gas Detectors:

Flammable Gas Detectors (Catalytic/IR): Monitor areas near equipment, pipelines, and storage units.

Toxic Gas Detectors (Electrochemical/MOS): Detect hazardous gases like H₂S and CO in refineries and drilling platforms.

Oxygen Detectors: Ensure O₂ levels remain within safe limits (19.5% – 23.5%).

Open-Path Detectors: Provide perimeter monitoring for facilities and pipeline networks.

Flame Detectors in the Oil and Gas Industry

A flame detector is a sensing device that detects electromagnetic radiation emitted by flames, enabling it to identify fires within milliseconds, even over considerable distances. This exceptional speed makes it a critical component in safety systems designed to prevent fires and explosions in oil and gas facilities.

Flame sensors operate on the principle of analyzing the electromagnetic spectrum emitted during combustion. Each fuel burns with a distinct spectral signature, often within the ultraviolet (UV) and infrared (IR) ranges. The detectors analyze this radiation to distinguish between actual flames and other sources of light or heat.

To clarify the differences between flame detector technologies in the oil and gas industry, the following table outlines the key principles, advantages, limitations, and applications of each type:

| Type | Principle | Advantages | Limitations | Applications |

|---|---|---|---|---|

| UV Detectors | Detect flame radiation in the 100–400 nm range | Ultra-fast response (<5 ms); sensitive to hydrocarbons | False alarms from lightning/welding; sensitivity degrades over time | Ideal for indoor or shaded areas |

| IR Detectors | Detect heat radiation at ≈4.4 µm using flicker technology | Resistant to smoke and lightning | Affected by hot furnaces or heavy fog | Suitable for outdoor areas |

| UV/IR Dual Detectors | Combine UV and IR for enhanced accuracy | High reliability; reduced false alarms | Higher cost | Common indoors and outdoors |

| Multi-Spectral IR (MIR) | Analyze IR radiation at multiple wavelengths | Highest immunity to false alarms; excellent performance in harsh conditions | Most expensive type | For critical high-risk areas |

Combustion flame sensor are fundamental to safeguarding lives and assets in the oil and gas industry. Their performance is measured by metrics such as response time (1–10 seconds), detection range (up to 60 meters), and field of view (90°–360°). Applications span drilling platforms, refineries, storage facilities, and turbine rooms.

Heat Detectors in the Oil and Gas Industry: Principles, Types, and Applications

A heat detector is a fundamental safety device within any fire protection system, designed to identify abnormal changes in ambient temperature.

It is not affected by combustion by-products such as smoke, dust, or light; instead, it directly monitors thermal energy—unlike smoke or flame detectors.

The following comparison table helps identify the most suitable detector based on the working environment and operational conditions:

| Type | Principle | Typical Oil & Gas Applications |

|---|---|---|

| Fixed Temperature | Activates when a predefined temperature threshold is exceeded | Storage rooms, equipment garages, vapor-filled enclosures |

| Rate-of-Rise | Detects rapid temperature increases regardless of absolute values | Limited use in industrial settings due to environmental variability |

| Linear Heat Cable | Heat-sensitive cable covering extended distances | Pipeline monitoring, conveyor belts, cable trays |

Critical Fire Suppression Systems and Technologies for Industrial Applications

Explosion and fire suppression technologies in oil & gas vary significantly based on the specific hazard profile. Foam systems are engineered to combat flammable liquid fires by forming an insulating blanket, while gas-based suppression systems are highly effective in enclosed spaces such as electronic equipment rooms and control centers. Water deluge and sprinkler systems, on the other hand, provide rapid cooling and fire spread control in high-risk areas.

1. Foam Suppression Systems

Foam systems extinguish Class B fires—particularly those involving hydrocarbons like crude oil and gasoline—by generating a thin cellular blanket over the liquid surface. This layer isolates the fuel from oxygen, suppresses vapors, and cools the material, effectively preventing re-ignition.

2. Gaseous Suppression Systems

Gaseous suppression systems operate in enclosed or confined spaces by either reducing oxygen concentration below the level required for combustion (oxygen deprivation) or inhibiting the chemical chain reaction of fire. These systems are ideal for protecting sensitive electronic equipment and control rooms where water-based suppression may cause collateral damage.

3. Water Deluge & Sprinkler Systems

Water-based systems, including deluge and sprinklers, suppress fires through three simultaneous mechanisms:

Cooling: Water absorbs immense amounts of heat due to its high thermal capacity and latent heat of vaporization.

Smothering: Steam generated from water evaporation displaces oxygen, disrupting the fire triangle.

Blanketing and Dilution: When used with foam additives, water forms an insulating layer over flammable liquids and dilutes the fuel to reduce combustibility.

These mechanisms make water-based systems exceptionally effective for controlling high-hazard fires in oil and gas facilities.

Design and Compliance Standards for Fire Suppression Systems in the Oil and Gas Industry in Dubai

The design and implementation of fire suppression systems in Dubai’s oil and gas sector adhere to a stringent, multi-tiered regulatory framework. This framework integrates federal and emirate-specific laws, internationally recognized standards such as NFPA and ISO/EN, and industry-specific best practices outlined by the American Petroleum Institute (API). This comprehensive approach ensures the highest levels of safety and regulatory compliance across all facilities.

1. Local UAE and Dubai-Specific Regulations

Local regulations form the foundational layer of compliance for fire suppression systems in Dubai’s oil and gas industry. These regulations enforce rigorous requirements for design, installation, and maintenance, with strict oversight by relevant authorities before operational permits are granted. Key details include:

Competent Authority: Dubai Civil Defense (DCD) is responsible for approving designs, conducting inspections, and ensuring compliance with safety standards.

Design Approval: All suppression system designs must be submitted to DCD for review and approval prior to installation.

Installation and Testing: Installation must be performed by DCD-approved contractors, followed by on-site inspections and performance tests before a No Objection Certificate (NOC) and operational permit are issued.

Reference to International Standards: Dubai’s fire codes often mandate adherence to international standards such as NFPA, effectively making them legal requirements within the emirate.

Other Local Authorities: Specific projects may require additional approvals from entities like Dubai Municipality (DM), Dubai Supreme Council of Energy (DSCE), or the Regulatory and Supervisory Bureau (RSB), alongside DCD compliance.

2. International Codes and Standards

Dubai’s local regulations incorporate international standards such as NFPA to establish the technical foundation for fire protection systems in the oil and gas sector, ensuring the highest levels of safety and performance in critical facilities.

Key Standards:

NFPA American Standards: Include NFPA 850 for power plants, NFPA 11 for foam systems, NFPA 13 for sprinklers, NFPA 2001 for critical rooms, and NFPA 15, 14, 20, and 24 covering all requirements for water-based and mechanical suppression systems.

ISO International Standards: Such as ISO 13702 for fire and explosion control in offshore facilities, and ISO 10418 for the design and testing of basic safety systems for surface operations.

American Petroleum Institute (API) Practices: Including API RP 14G for offshore platforms, API RP 2001 for refineries, and API 2030 for the application of fixed water spray systems.

ATEX and IECEx Standards: Ensure all electrical equipment in classified hazardous areas (Zones 1, 2) is intrinsically safe and does not constitute an ignition source.

3. Design Process and Compliance Workflow

The design and implementation of suppression systems in Dubai follow a structured workflow to ensure compliance with local and international standards, from risk analysis to annual inspections. Key stages include:

Hazard Analysis and Classification:

Identify fire types (e.g., hydrocarbon pool fires, jet fires, gas leaks, electrical fires).

Assign required protection levels (e.g., SIL ratings for systems).

System Selection:

Deluge Systems for process areas.

Foam Systems for storage tanks.

Clean Agent Systems for control rooms.

Standards-Based Design:

Strict adherence to NFPA, API, and ISO requirements.

Submit detailed drawings, hydraulic calculations, equipment specifications, and compliance documentation to DCD.

Installation and Commissioning:

Execution by DCD-approved contractors.

Comprehensive testing witnessed by DCD inspectors, including flow tests, alarm verification, and functional checks.

Certification and Operational Permits:

Upon successful testing, DCD issues a No Objection Certificate (NOC) and operational permit.

The Future of Oil and Gas Firefighting: Innovation and Artificial Intelligence

The future of firefighting in the high-stakes oil and gas industry is being radically transformed by innovation, moving from a reactive to a predictive and proactive model. Central to this transformation are Remote Control Systems and Drone Technology, integrated with Artificial Intelligence (AI) and Internet of Things (IoT) capabilities.

Conclusion

fire suppression systems in the oil and gas sector represent a fundamental pillar of industrial safety. They are not merely technical equipment but rather an integrated system designed to mitigate risks, protect lives, and ensure operational continuity. The stringent adherence to international standards such as NFPA and API, coupled with local regulations enforced by Dubai Civil Defense, has proven to be the optimal approach for achieving the highest levels of safety.

With accelerating technological advancements, these systems are poised to enter a new era driven by artificial intelligence solutions, unmanned aerial vehicles, and smart digital platforms. These innovations will enable faster, more efficient, and precise emergency responses. Consequently, investing in the development of suppression systems is no longer optional but a strategic imperative—ensuring operational sustainability and fortifying critical infrastructure against the most severe threats.

Looking for certified fire suppression solutions in the UAE? Trust DAEM CONTRACTING COMPANY to design, install, and maintain systems built to global standards.

Frequently Asked Questions about Fire Alarm Systems

1.Is CO2 suppression still a good choice for compressor stations, or is INERGEN/Nitrogen better?

For new installations, INERGEN or a Nitrogen-based system is almost always the superior and safer choice.

2. 2. How often do you actually test your foam suppression systems? And how much does a full test cost?

The UAE requires annual foam system testing per Civil Defense regulations, with costs ranging from $50,000 to $200,000 depending on system size and environmental containment requirements.

3. Is it worth investing in "clean agent" systems (like FM-200) for a control room, or is a good CO2 system sufficient?

The UAE prohibits CO2 in occupied control rooms; clean agent systems are mandatory for critical facilities to protect both personnel and sensitive equipment from suppression damage.

4.What's the biggest challenge in maintaining fire protection systems in a harsh offshore environment?

The UAE’s offshore operators face extreme corrosion from Gulf conditions and logistical complexities in transporting personnel and equipment for maintenance under challenging weather.

M. Hussam Almahmoud

Business Owner | DAEM CONTRACTING LLC Dubai

M. Hussam Almahmoud Graduated From Aleppo University BSC in Mechanical Engineering, CEO and partner In White Eagkes Hen trd ( established in 2005 , White Eagle Transport Est 2008 , City care Fire Est 2010 , Daem Contracting Est 2014 , Abraj Wa Mabani cont Est 2016 , White eagles gen trd LTD Est 2021 in Manchester UK , Partner in ICE Elektronik Dis Ticarat limited Sirketi Istanbul turkey

Comments are closed