A commercial kitchen fire suppression system is an advanced safety mechanism designed to safeguard lives and property in the high-risk environment of professional cooking. These systems integrate wet chemical agents, stainless steel piping and nozzles, and intelligent detection and control units to deliver an immediate and reliable response.

Upon detecting a fire—through fusible links, thermal sensors, or electronic detectors—the system automatically activates within 3 to 10 seconds. It releases the wet chemical agent, shuts off gas and electrical supplies, and triggers both audible and visual alarms.

The chemical rapidly cools overheated oils, forms a protective soap-like barrier, and prevents dangerous re-ignition. For example, in a busy restaurant kitchen where deep-frying is continuous, this rapid activation can mean the difference between a minor flare-up and a devastating fire.

In the UAE, compliance is mandatory. Systems must be designed and installed according to the Emirates Authority for Standardization & Metrology (ESMA) and the UAE Fire & Life Safety Code under Dubai Civil Defense (DCD). To align with international benchmarks, approvals based on NFPA 96 and UL 300 are also required, ensuring that kitchens meet both local and global safety expectations.

Modern solutions further enable smart integration—including remote monitoring, instant alerts, and automated power shut-off—providing operators not only with legal compliance but also with peace of mind, operational continuity, and protection against liability.

Table of Contents

What Is a Commercial Kitchen Fire Suppression System and What Are Its Core Components?

A commercial kitchen fire suppression system is an automatic extinguishing solution engineered to combat the unique fire hazards of professional cooking environments. It primarily uses wet chemical agents, most commonly potassium acetate or potassium carbonate, which are designed to suppress Class K and Class F fires caused by hot oils and grease.

When discharged, the agent reacts with burning fats through a process called saponification, forming a thick soap-like layer that cuts off oxygen and cools the oil temperature to below 93°C (200°F)—well under its ignition point. This dual action not only extinguishes the flames but also prevents dangerous re-ignition.

Unlike portable fire extinguishers, these systems are permanently installed and configured to protect cooking appliances, exhaust hoods, and ductwork, ensuring complete coverage across the kitchen. To guarantee reliability, they must comply with international standards such as UL 300 and NFPA 17A, as well as local UAE requirements under Dubai Civil Defense (DCD) and ESMA certification.

By providing targeted, rapid suppression, these systems minimize downtime, reduce property damage, and most importantly, safeguard staff and customers in high-risk food preparation environments.

A commercial cooking area fire suppression system is made up of several interconnected components that work together to detect and extinguish fires quickly and effectively:

- Hood and Appliance Nozzles (Stainless Steel Nozzles):

Small, corrosion-resistant nozzles positioned above cooking surfaces and inside exhaust hoods. They discharge the wet chemical agent directly onto hot oils, flames, and grease-laden vapors. - Detection System:

A network of heat-sensitive fusible links, thermal cables, or electronic sensors that constantly monitor kitchen conditions. When temperatures reach a critical threshold—typically 165°C to 200°C (329°F–392°F)—the detection system automatically triggers the suppression release. - Agent Cylinder (Wet Chemical Tank):

A pressurized steel cylinder filled with the wet chemical agent (commonly potassium acetate). In many systems, a secondary nitrogen cartridge provides the force required to expel the agent through the piping network. - Automatic Shut-Off Valves (Gas/Electric):

Solenoid valves and circuit breakers linked to the system immediately cut off fuel and electrical power to cooking equipment, preventing continued ignition or re-ignition. - Manual Pull Station:

A clearly marked red lever, usually installed near the kitchen exit, allows staff to manually activate the system if the automatic trigger fails or in case of an emergency. - Control Panel: The “brain” of the system, connecting detectors, cylinders, and nozzles. It processes sensor signals, issues activation commands, and triggers alarms.

- Discharge Piping:

A network of black steel or stainless-steel pipes that channels the wet chemical agent from the cylinder to the nozzles, ensuring reliable distribution. - Cooking Surface Nozzles: Dedicated nozzles installed directly above fryers, grills, and ranges. They provide targeted coverage across hot surfaces to guarantee complete extinguishment.

By combining these components into a unified system, commercial kitchens achieve rapid detection, automatic suppression, and compliance with UAE Fire & Life Safety regulations, while also minimizing operational downtime after an incident through reliable Fire Alarm Systems in the UAE that ensure both safety and certification.

How a Commercial Kitchen Fire Suppression System Works

A Commercial cooking area fire suppression system operates in a well-defined sequence designed for speed, reliability, and compliance with UAE safety codes:

- Detection (0–5 seconds):

Heat or flames are identified through fusible links, thermal sensors, or electronic detectors. Once the temperature threshold is exceeded, the system sends a signal to the control panel. - Activation (3–10 seconds):

- Automatic Mode: The system triggers a nitrogen cartridge, which pressurizes the agent cylinder and forces the wet chemical agent through the discharge piping to the nozzles.

- Manual Mode: If automatic detection fails, staff can activate the manual pull station—a legal requirement under the UAE Fire & Life Safety Code.

- System Response: Simultaneously, the system:

- Shuts off gas and electricity to all connected cooking equipment.

- Activates audible and visual alarms to alert kitchen staff.

- Suppression:

The wet chemical agent is discharged over the cooking surfaces. Through a reaction called saponification, it forms a protective foam-like layer that smothers oxygen, cools the oil below 93°C (200°F), and prevents dangerous re-ignition. - Containment: Additional nozzles inside the hood and ductwork ensure that flames do not spread through the ventilation system.

- Post-Discharge Protocol:

- Cooking appliances remain locked out until the system is reset.

- By UAE law, the system must be recharged and inspected within 24 hours by a licensed contractor approved by Dubai Civil Defense.

- Regular maintenance and certification are mandatory to keep the system compliant and operational.

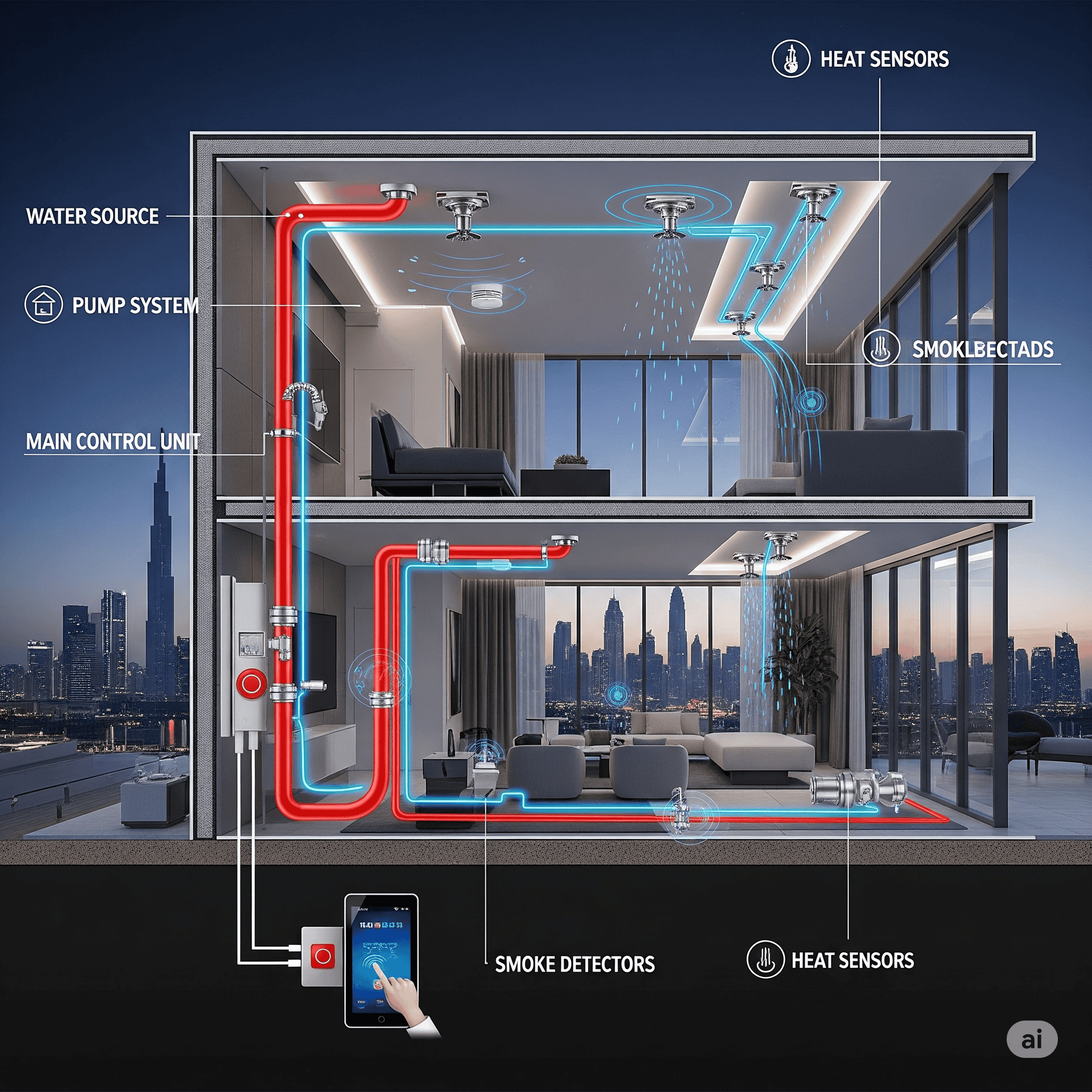

his structured process ensures that fires are detected, suppressed, and contained within seconds, protecting both life and property while meeting strict UAE Civil Defense regulations. For added peace of mind at the residential level, consider a Fire Suppression System for Home – Because Safety Should Be Automatic!

Designing Commercial Kitchen Fire Suppression Systems in the UAE

Designing a fire suppression system for commercial kitchens in the UAE requires strict adherence to the UAE Fire & Life Safety Code, along with compliance to international benchmarks such as UL 300, NFPA 17A, and NFPA 96. The system must:

- Provide complete coverage for all cooking appliances, exhaust hoods, and ductwork.

- Include both automatic detection (heat sensors or fusible links) and a manual pull station as a mandatory backup.

- Incorporate gas and electrical shut-off mechanisms to immediately cut off energy supply in case of fire.

- Be integrated with the building’s fire alarm system, ensuring immediate notification and coordinated emergency response.

The design and approval process typically follows a five-step sequence:

- Engineering Design: Prepared by a licensed fire protection engineer, ensuring compliance with UAE and NFPA standards.

- Civil Defense Approval: Submission of design drawings and specifications for review and approval by Dubai Civil Defense (DCD).

- Installation: Carried out by an authorized contractor, such as DAEM Dubai Contracting, using ESMA-certified components.

- Testing & Commissioning: Includes a full acceptance test under DCD supervision to verify performance.

- Ongoing Maintenance: By law, systems must undergo bi-annual inspections and servicing by a certified technician to maintain compliance.

By following this structured process, businesses ensure not only legal approval but also operational reliability, staff safety, and protection from costly shutdowns. For example, delays in approval due to design flaws can leave investors stuck after they’ve Paid a Full Year’s Rent for a Restaurant in Dubai—But Still Can’t Open.

Common Design Mistakes in Commercial Kitchen Fire Suppression Systems: Ventilation and Equipment Spacing

The most frequent causes of rejection for fire suppression systems in UAE commercial kitchens are related to ventilation layouts and equipment spacing. Typical mistakes include improper nozzle distribution inside hoods and ducts, insufficient clearance between cooking appliances, the use of non-approved duct materials, and lack of integration with automatic gas/electric shut-off systems and fire alarm panels.

Such violations almost always result in Dubai Civil Defense (DCD) refusing approval during inspection, forcing contractors to redesign and re-install the system—leading to costly delays and potential penalties.

To illustrate these issues clearly, the table below highlights the most common design errors, their corresponding legal requirements under UAE fire codes, and the associated risks.

Common Mistake | Legal Requirement | Resultant Risk |

Undersized Hood (smaller than the cooking appliances) | The hood must extend at least 150 mm (6 inches) beyond the edges of the appliances, as per UAE Fire & Life Safety Code | Grease accumulation outside the suppression spray zone, creating a highly flammable hazard |

Incorrect Spacing Between Cooking Appliances | A minimum clearance of 450 mm (18 inches) between fryers, or installation of an approved thermal barrier, is required under UAE Fire & Life Safety Code. | Rapid flame spread between appliances, increasing the likelihood of uncontrollable kitchen fires. |

Nozzles Installed at the Wrong Angle or Off-Center from the Appliance | Spray must be directed at the center of the cooking surface within ±10°, following the manufacturer’s installation guidelines | Extinguishing agent fails to reach hot oil or grease effectively, resulting in incomplete suppression and risk of re-ignition |

Use of Non-Compliant Duct Materials (Aluminum or Galvanized Steel) | Ducts must be constructed from stainless steel with a minimum thickness of 1.2 mm, combined with fire-rated insulation, in accordance with UAE Fire & Life Safety Code | Duct collapse during a fire and uncontrolled flame spread through the ventilation system to other parts of the building |

Failure to Integrate the System with the Fire Alarm Panel or Gas/Electric Shut-Off | The suppression system must automatically cut off gas and electricity supplies and activate both audible and visual alarms upon discharge, as mandated by UAE Fire & Life Safety Code. | Continuous fueling of the fire with gas or electricity, leading to system failure and uncontrolled fire escalation. |

To avoid these risks altogether, trust Fire Systems Services and Solutions by Daem Contracting—your partner in fully compliant design, installation, and approvals across the UAE.

Building-Compliant Fire Suppression Systems for Commercial Kitchens in the UAE

To design a Restaurant kitchen fire suppression system that fully complies with UAE regulations, nozzles must be installed to cover all cooking surfaces at a height of ≤0.9m, with additional nozzles inside exhaust ducts every 3 meters at a spray angle of 80° ± 5°. All nozzles should be manufactured from Stainless Steel 304 to ensure long-term corrosion resistance.

The system must use ESMA-approved wet chemical agents such as potassium carbonate or acetate-based solutions. These agents extinguish flames by creating a soap-like layer while rapidly reducing oil temperature to below 93°C, with a minimum discharge rate of 6L/min per nozzle.

Integration with 24V DC shut-off valves is mandatory to cut off gas and electricity within 10 seconds of fire detection. At the same time, exhaust fans must be automatically shut down to prevent flame spread—ensuring full regulatory compliance and protection against fines.

1 – Fire Suppression Nozzle Requirements According to Dubai Guidelines

Dubai regulations require that nozzles cover all cooking surfaces at a maximum height of ≤0.9 m, with the number of nozzles determined by the size of the cooking surface to ensure full coverage.

Requirement | Technical Specification |

Nozzle placement over cooking appliances | ≤0.9 m height, full surface coverage |

Number of nozzles | Based on cooking surface size (complete coverage) |

Spray angle | ~80° |

Exhaust duct nozzle spacing | Every 3 meters along duct length |

Nozzle type | Vortex nozzles (smoke-penetrating) |

Nozzle material | Stainless steel |

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2 – Wet Chemical Agents: Suppression Science Aligned with UAE Regulations

In the UAE, only ESMA-approved wet chemical agents are permitted, typically potassium carbonate (K₂CO₃) or potassium acetate-based formulations. These agents are designed to smother flames, cool hot oils, and form a protective layer that prevents re-ignition.

Requirement | Technical Specification |

Type of agent | Potassium carbonate (K₂CO₃) or acetate-based agents (ESMA-approved) |

Effective concentration | ≥20% potassium carbonate recommended for effective suppression |

Discharge rate per nozzle | ≥6 liters per minute |

Non-compliance penalty | System approval rejected; equipment confiscated if non-approved agents used |

3 – Automatic Shut-Off: Legal Requirements for Commercial Kitchens in the UAE

UAE law mandates that commercial kitchens integrate 24V DC solenoid gas valves and electrical circuit breakers with their fire suppression systems. These must cut off fuel and electricity within 10 seconds of activation. Non-compliance may result in heavy fines or suspension of the operating license until corrections are made.

Component | Legal Requirement | Penalty |

Gas Shut-Off Valves | 24V DC solenoid valves connected to the suppression system | Fine up to AED 30,000 |

Response Time | Must cut off fuel supply within ≤10 seconds of activation | Temporary license suspension / kitchen closure until corrected |

Electrical Shut-Off | Circuit breakers integrated with the suppression system | Rejection of approval by Dubai Civil Defense (DCD) |

Regulatory Framework for Commercial Kitchen Fire Suppression Systems in the UAE

The regulatory framework for Food service kitchen fire suppression systems in the UAE is built on two key authorities:

- Dubai Civil Defense (DCD): Responsible for reviewing and approving system designs, conducting on-site inspections, issuing approvals, and enforcing penalties for violations.

- Emirates Authority for Standardization and Metrology (ESMA): Responsible for certifying system components and wet chemical agents to ensure they meet safety and performance standards.

According to the UAE Fire & Life Safety Code:

- Every system must obtain an ESMA certificate of conformity.

- Designs must be prepared by a licensed fire protection engineer.

- Installation must be carried out by a DCD-approved contractor, such as DAEM UAE Contracting.

- Systems are legally required to undergo bi-annual maintenance by a certified technician.

⚖️ Non-compliance may lead to heavy fines, rejection of system approval, or even suspension of the kitchen’s operating license—ensure your Fire Suppression System meets all standards and secure your Dubai Civil Defense Approval seamlessly with DAEM Services Approvals

Future Trends: Commercial Kitchen Fire Suppression Systems in the UAE

The future of fire suppression systems in UAE commercial kitchens is moving toward smart, connected, and sustainable solutions:

- Artificial Intelligence (AI) and IoT Integration:

Early fire prediction, remote monitoring, and real-time data analytics reduce system failures and accelerate emergency response. - Eco-Friendly Materials:

Development of plant-based suppression agents and recyclable piping to meet environmental goals, with the challenge of maintaining high heat resistance. - Smart City Integration:

Direct connection to the Dubai Smart Platform enables instant alerts and reduces response time to under 3 minutes. Maintenance is enhanced with the adoption of smart service cards. - Compact & Wireless Systems:

Next-generation integrated systems save space and operate via wireless activation, increasing flexibility in modern kitchen layouts. - Augmented Reality (AR) Training:

Staff can practice emergency response procedures in simulated environments, improving readiness and safety culture.

⚠️Challenges remain: Higher costs (20–30% increase compared to conventional systems), the need for updated legislation, and stronger cybersecurity protections for IoT-enabled systems—learn more about the difference between conventional and addressable fire alarm systems and choose the best solution for your building in the UAE.

Kitchen Safety Starts Today: Smart Protection, Guaranteed Performance, and Peace of Mind

Commercial kitchen fire suppression systems provide reliable protection for both lives and property through rapid heat detection, automatic discharge of wet chemical agents, and immediate shut-off of gas and electrical supplies.

When designed and installed in line with Dubai Civil Defense (DCD) and ESMA regulations, these systems ensure full compliance while paving the way for the future of safety—integrating AI, remote monitoring, eco-friendly suppression agents, and smart city connectivity, while addressing modern challenges such as higher costs, cybersecurity, and evolving legislation.

🤝 Your Trusted Partner in Safety and Innovation – DAEM Contracting Company.

We guarantee the design and installation of fully compliant, future-ready fire suppression systems that protect your business, safeguard your staff, and keep you aligned with the latest UAE standards and technologies.

Frequently Asked Questions:

1. Why do regular fire extinguishers fail to suppress grease fires (Class K)?

Standard extinguishers are ineffective against Class K grease fires because they cannot cool the oil below 93°C (200°F). Water makes the situation worse, causing explosive steam reactions, while dry chemical and CO₂ extinguishers only provide temporary suppression. The only effective solution is a wet chemical fire suppression system, which cools the oil and creates a soap-like barrier that prevents re-ignition.

2. Can I install a used fire suppression system in a commercial kitchen in the UAE?

Yes, used systems are permitted only if they are approved by Dubai Civil Defense (DCD) and meet all requirements of the UAE Fire & Life Safety Code. The system must be in good condition, free of defects, and installed by a licensed contractor. Non-compliant or uncertified systems may result in fines or closure of the facility.

3.Why is the cost of maintaining a fire suppression system higher than the system itself?

Maintenance requires specialized technicians, replacement of chemical agents, nozzle and pipe testing, and compliance with strict UAE safety standards. These recurring requirements make maintenance costs higher than the one-time cost of system installation.

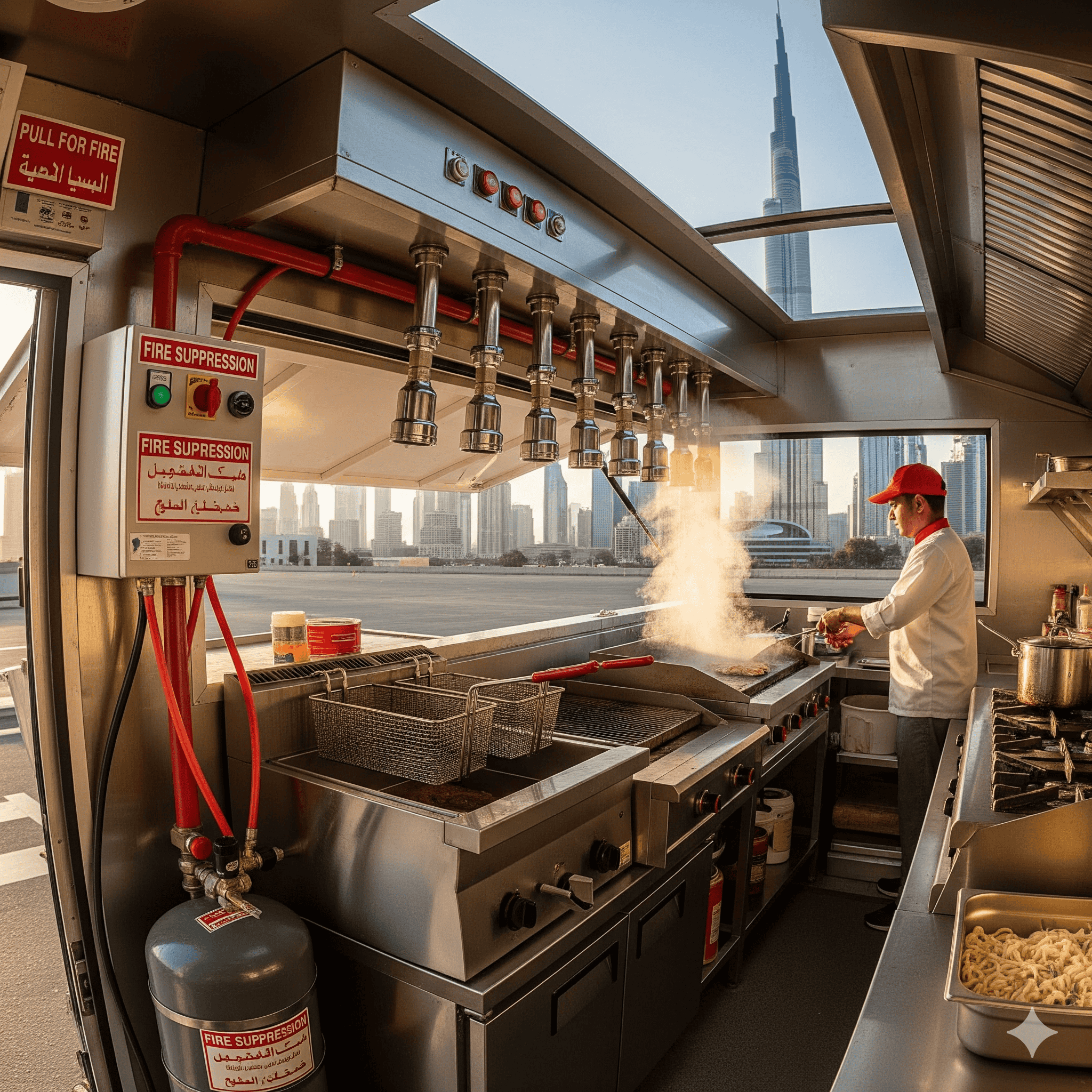

4. Are fire suppression systems required for food trucks in the UAE?

Yes. Fire suppression systems are mandatory for food trucks, not optional. The compact and enclosed nature of food trucks, combined with intensive cooking equipment (gas burners, deep fryers, ovens), creates a high fire risk that requires dedicated suppression protection.

5. Can I use a European fire suppression system in Dubai?

Yes, provided the system is approved by Dubai Civil Defense (DCD) and meets all technical specifications outlined in the UAE Fire & Life Safety Code.

6. How long does it take to get approval for a fire suppression system in Dubai?

Approval timelines typically range from 3 to 8 weeks for medium-sized projects. The exact duration depends on project complexity and the quality of the application submission.

📌 To simplify the process and ensure full compliance, contact DAEM Contracting for end-to-end Fire Systems Services and Solutions.

Comments are closed