Oil well sites and remote storage facilities in the UAE face high fire and safety risks due to flammable hydrocarbons and harsh operating conditions.

The remoteness of these sites makes rapid emergency response challenging, making Civil Defence-approved fire suppression UAE, fire suppression systems, and advanced fire protection systems essential.

Integrated fire alarm systems and fire alarm components, compliant with the UAE Fire Code and Fire and Life Safety Code, ensure protection of personnel, equipment, and uninterrupted operations, while solutions like foam fire suppression for oil storage and clean agent suppression systems UAE deliver effective, residue-free fire control.

Table of Contents

What is a Fire Suppression System for Well Sites and Remote Storage?

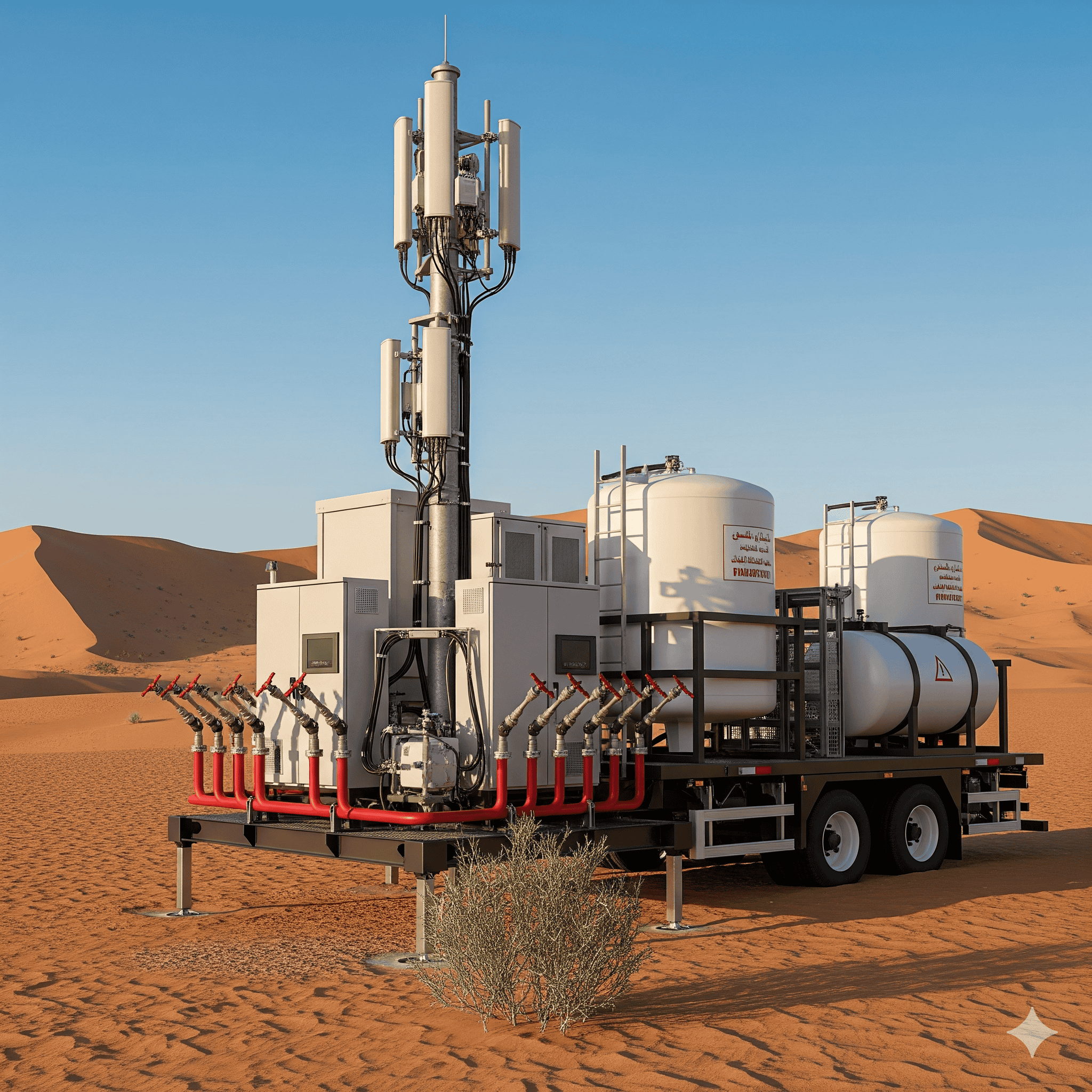

A fire suppression system for well sites and remote storage is an advanced fire suppression system that automatically detects and extinguishes fires in isolated, high-risk locations.

It integrates detection, control, and suppression components, using agents such as clean agents (FM-200 / Novec 1230) to protect critical equipment and operations from damage and downtime.

The system relies on detectors like heat or smoke sensors to trigger alarms and release the suppressant. Designed to withstand harsh environments, it is compact, modular, and a reliable alternative to traditional water-based systems, fully compliant with the UAE Fire Code and industry fire protection systems standards.

What are the Components of a Fire Suppression System for Well Sites and Remote Storage?

A fire suppression system for oil wells UAE consists of detection systems, such as smoke detectors, that monitor for early signs of fire, Once an alarm is triggered, the signal is transmitted to the main control unit, which assesses the situation and decides to activate the suppression systems, releasing gases or foam through a piping network to quickly extinguish the flames.

To ensure operational continuity, the system is supported by infrastructure such as water tanks and emergency pumps.

Finally, protection is completed with manual firefighting equipment, enabling emergency response teams to intervene directly when necessary.

A detailed overview of the system’s components highlights the interconnected units of this fire protection system:

1. Detection System:

Components responsible for monitoring fire indicators and providing early alerts as part of a comprehensive fire protection system:

Smoke detectors for early detection inside enclosed buildings.

Heat detectors that respond to temperature increases.

Flame detectors (infrared/ultraviolet) for ultra-fast response to fires in open areas—critical for oil wells and remote storage.

Manual pull stations allow personnel to manually activate the fire alarm system.

2. Control and Operating System

Includes essential fire alarm components to manage alerts and suppression activation:

Fire alarm control panel: The system’s brain, receiving signals from detectors and controlling suppression and alarm components.

Electrical control components: Abort switches to cancel automatic activation if safe, and manual release stations.

Notification appliances: Sirens and strobe lights to warn personnel before agent discharge.

Primary and backup power supplies: Diesel generators and UPS to ensure continuous operation in remote locations.

3. Suppression System

Releases appropriate suppression systems agents to extinguish fires quickly and effectively:

Foam: Primary agent for flammable liquid (oil) fires in yards and around tanks.

Dry chemical: Rapid suppression around wellheads and loading areas; interrupts the fire’s chemical reaction.

Clean agents (FM-200 / Novec 1230): Used in electrical control rooms and sensitive equipment; residue-free and absorb heat.

Water: Sprinkler or deluge systems to cool fires over large areas.

Storage cylinders/tanks: Store suppression agents (foam concentrate, compressed gas) until needed.

Piping network and nozzles/sprinklers: Deliver agents from storage to designed nozzles for full coverage.

4. Manual Firefighting Equipment

Enables rapid manual intervention for personnel as part of a certified fire safety system:

Fire hoses and water pumps.

Portable fire extinguishers of various types.

Protect your facilities with expert Fire Suppression for the Oil and Gas Industry from DAEM Fire System Installation Company—contact our UAE team today for professional design, installation, and maintenance services.

Types of Fire Suppression Systems for Well Sites and Remote Storage: A Comprehensive Guide to Automatic Protection in Remote Areas

The types of fire suppression systems used at well sites and remote storage include foam fire suppression for oil storage, which effectively controls flammable liquid fires; dry chemical fire suppression, ideal for rapid response around wellheads; and clean agent suppression systems, designed to protect sensitive equipment. Moreover, water mist systems are employed for cooling and preventing fire spread, while CO₂ fire suppression is used to smother flames in unmanned areas.

The table below outlines key fire protection solutions, their targets, agents, and suitability for remote sites:

| System | Target | Agent | Suitability for Remote Sites | Key Features |

|---|---|---|---|---|

| Foam | Flammable liquids | Foam | ⭐⭐⭐⭐⭐ | Large-area coverage, cools and isolates oxygen |

| Dry Chemical | Rapid fires & explosions | Chemical powder | ⭐⭐⭐⭐⭐ | Quick suppression around wellheads |

| Clean Agent | Sensitive equipment | Novec 1230 / FM-200 | ⭐⭐⭐⭐ | Non-conductive, residue-free |

| Water Spray / Deluge | Cooling & structure | Water | ⭐⭐⭐ | Limited applicability, prevents spread |

| CO₂ | Unmanned areas | CO₂ gas | ⭐⭐⭐ | Effective but hazardous in occupied areas |

Design and Testing Requirements for Fire Suppression Systems in Well Sites and Remote Storage in the UAE

In the UAE oil and gas sector, fire suppression systems for well sites and remote storage must comply with Civil Defence codes, NCEMA standards, and NFPA guidelines.

They rely on smart detection, certified suppression agents, and robust infrastructure with backup power and monitoring. With preventive maintenance, training, and sustainable technologies, these systems ensure safety, compliance, and reliable protection in even the most challenging environments.

To better understand the requirements, the key elements can be outlined as follows:

Regulatory compliance: Adherence to UAE Civil Defence codes and NCEMA specifications, applying the latest NFPA editions with priority given to local regulations, in addition to obtaining official approvals before implementation.

Technical design: Conduct comprehensive risk assessments covering stored materials, climatic conditions, and hazard classification; adopt intelligent detection systems (heat, smoke, flame, flammable gas) resistant to harsh conditions.

Suppression systems: Use foam systems compliant with NFPA 11 and 16 with operational capacity of up to 120 minutes and precise automatic mixing systems; optional clean agent systems compliant with NFPA 2001 and environmentally friendly.

Infrastructure and installation: Use approved materials and equipment (316L stainless-steel pipes, UL/FM-approved pumps, explosion-proof electrical fittings); ensure primary and backup power sources (diesel generator + UPS) and centralized control systems.

Monitoring and communications: Implement continuous satellite monitoring and bidirectional data communication; multi-level alarm systems integrated with Emergency Shutdown (ESD) and early warning systems.

Documentation and testing: Prepare risk assessment reports and approved design plans; provide equipment compliance certificates; conduct integrated pressure and performance tests with realistic emergency simulations.

Maintenance and training: Adopt a preventive maintenance program (weekly checks, quarterly maintenance, annual testing); provide periodic hands-on training with field emergency simulations and protocol updates.

Local considerations: Design systems to withstand high temperatures and sandstorms; implement tank cooling solutions; comply with administrative requirements (Civil Defence permits, compliance certificates, electronic maintenance records).

Innovation and sustainability: Apply smart technologies (IoT, AI for incident prediction, automated reporting); use recycled water systems, eco-friendly materials, and energy-efficient solutions.

Protect your mobile facilities from fire hazards with advanced solutions—our team in the UAE provides expert Fire Suppression Systems for Mobile Stations, ensuring safety and compliance.

Conclusion:

By combining early detection, automatic suppression, and intelligent monitoring, well sites and remote storage can now tackle severe fires with high efficiency—even in isolated locations with delayed response times. Backed by compliance with international standards and strengthened by innovation and sustainability, these systems go beyond firefighting tools; they secure operational continuity and safeguard both people and assets in the most demanding oil and gas environments.

💡 Looking for a Daemuae Company you can trust to keep your operations safe and compliant?

📩 Contact us today and let our experts design, install, and maintain a solution tailored to your needs.

Frequently Asked Questions:

1- What is the cost of installing a Civil Defence-approved fire suppression system in the UAE??

Fire suppression system UAE prices for oil and gas facilities typically range from AED 50,000 to AED 500,000.

The exact cost depends on several factors such as site size, selected suppression agent (foam, clean agent, CO₂, or water mist), system design, and regulatory approvals. Certified providers, such as DAEM Fire Systems Services and Solutions, ensure not only competitive pricing but also full compliance with UAE Civil Defence requirements and international standards.

2- How often should fire suppression systems undergo maintenance in remote oil and gas facilities?

Fire suppression systems in the UAE require weekly inspections, quarterly servicing, and annual testing to meet Civil Defence standards.

3- Are clean agent suppression systems safe for sensitive equipment?

Yes, clean agent fire suppression systems UAE are residue-free and non-conductive, making them ideal for control rooms and electronics.

4- What are the benefits of foam fire suppression for oil storage tanks?

Foam fire suppression UAE provides wide coverage, cools flammable liquids, and isolates oxygen to control tank fires effectively.

5- How do fire alarm components integrate with suppression systems?

The Essential Components of a Fire Alarm System work together with suppression systems through integrated control panels, where detectors send signals that automatically activate the chosen suppression agent.

Comments are closed