Restaurant suppression systems are essential because they directly moderate the extreme fire risks inherent in commercial kitchens, including open flames, superheated oils, pressurized gas, and high-output appliances, all of which contribute to a high risk of ignition.

For restaurant owners, installing a fire suppression system is not optional; it is a legal requirement, and a strategic safeguard for business continuity, because they are designed to detect and extinguish fires rapidly, minimizing downtime and liability.

Securing your Restaurant approval also ensures your establishment meets all regulatory standards, keeping your operations safe and compliant.

This guide outlines how to implement, operate, and maintain a restaurant fire suppression system that meets NFPA and DCD standards, ensuring full compliance and maximum protection.

For expert assistance and approved solutions in Dubai, we invite you to visit Daem Contracting LLC, your trusted partner in fire safety and regulatory approvals

Table of Contents

What Is A Restaurant Fire Suppression System?

A restaurant fire suppression system is an automatic safety system installed in commercial kitchens to detect and extinguish fires caused by grease, oils, fats, and high-temperature appliances.

When the system detects extreme heat or flames, it activates a network of pipes and nozzles –located over cooking areas– that discharge a wet chemical agent which reacts and forms a fire-smothering foam. At the same time, the control panel of the suppression system shuts off the gas supply and activates the exhaust hood to clear the smoke.

This sequence of actions taken by the kitchen suppression system is essential for minimizing damage, protecting staff, and preventing fire escalation in high-risk cooking environments.

Once triggered, the system activates a control head that performs multiple safety responses:

- Early fire detection through heat sensors or fusible links.

- Rapid suppression at the source by releasing a UL 300–listed wet chemical agent (e.g., potassium carbonate).

- Formation of a protective foam layer that cools surfaces and prevents re-ignition.

- Automatic shutdown of gas and electrical supply to cooking equipment.

- Activation of the exhaust hood and ventilation system to remove smoke and vapors.

These functions work together to minimize fire damage, protect staff and guests , and prevent escalation in high-risk cooking environments.

In Dubai , the installation of such systems is mandatory under Dubai Civil Defence (DCD) safety codes and aligned with international standards such as NFPA 96 and UL 300. Compliance ensures not only safety but also business continuity and licensing approval.

How Fire Suppression Systems in Restaurants Work

Fire suppression systems in restaurants work by automatically detecting high heat or fires through heat sensors or fusible links, cutting off fuel sources, and releasing a wet chemical agent to extinguish the fire.

The kitchen fire suppression system is activated without manual input, minimizing damage and ensuring safety.

Once triggered, heat sensors above the cooking appliances signal the fire suppression system to shut off the gas supply and activate fire extinguishing nozzles installed over cooking equipment which release a wet chemical agent that reacts with grease to form a fire-suppressing foam. At the same time, the exhaust hood turns on to clear smoke and vapors.

After extinguishment, the chemical agent cools surfaces and prevents re-ignition, making cleanup easier, and allowing kitchens to resume operations quickly. For added fire hazards safety, a manual pull station should be installed near the kitchen exit to allow staff to activate the system if needed.

To understand how fire suppression systems function in real-world scenarios, here is a step-by-step overview of how these systems detect, respond to, and contain kitchen fires:

1- Cooking Areas Monitoring

Heat sensors installed above cooking appliances and inside the kitchen hood to monitor temperature levels. When excessive heat is detected, the system is immediately triggered to prevent fire ignition, as required by NFPA 96 and Dubai Civil Defence (DCD) codes. These sensors serve as the first line of defence, ensuring real-time surveillance.

2- Fire Detection

Heat sensors or fusible links continuously monitor the cooking environment. When the sensors detect abnormal heat or open flames, the system automatically engages the fire suppression sequence.

This sequence of events ensures immediate and effective response even if kitchen staff are unaware or occupied, minimizing the risk of escalation.

3- Agent Discharge

Upon activation, specialized nozzles mounted above the hazard discharge the extinguishing agent (mostly a wet chemical like potassium acetate). This agent rapidly cools surfaces and reacts with grease to form a soap-like barrier, effectively smothering the fire and preventing re-ignition.

4- Fuel/Energy Cutoff

As the extinguishing agent is released through overhead nozzles, the system simultaneously shuts off gas and electrical supply to the affected cooking equipment using automatic valves and switches.

This coordinated action prevents the fire from spreading, removes fuel sources, and lowers the risk of re-ignition — ensuring safer containment and faster recovery.

5- Alarm Activation

The fire suppression system also signals the building’s fire alarm and may send alerts to a central monitoring station or local fire department. This ensures timely evacuation and coordinated emergency response across the facility.

6- Post-Fire Procedures

Modern wet chemical agents –such as potassium acetate, potassium carbonate, and potassium citrate– not only extinguish flames, but also leave behind a protective layer that prevents re-ignition.

Compared to older powder systems, wet chemical systems simplify post-fire cleanup and allow kitchens to resume operations more quickly.

7- Manual Activation

As a backup, a manual pull station is typically installed near the kitchen exit which allows staff to activate the wet chemical fire suppression system by pulling a handle if a fire is noticed before the automatic system is triggered.

Key Components of Commercial Kitchen Fire Suppression System

The core components of fire suppression systems for cooking areas are heat sensors that identify extreme temperature levels (600°F to 750°F or ≈ 315°C to 399°C) above cooking appliances and instantly signal the central control panel.

Acting as the system’s brain, the panel triggers the release of the wet chemical agent, which is then discharged through a network of nozzles and piping to suppress the hazard precisely at its source.

1- Fire Detection Sensors

Fire Sensing Units are heat-sensitive devices that melt at a certain temperature (135°F to 194°F or 57°C to 90°C) and are installed above cooking appliances and inside exhaust hoods to set off the system when these dangerous heat levels are detected.

Some fire detection systems use specialized linear detection tubes that act as a continuous line of detection.

Advanced fire detection models can distinguish between false alarms such as steam, smoke, or high cooking heat and actual fire conditions which involve sustained high temperatures, rapid heat rise, or visible flames that indicate a genuine ignition risk. This ensures the system responds only when a true fire hazard is present, reducing downtime and preserving agent reserves.

2- Nozzles and Distribution Piping

Discharge nozzles and pipework form a network of stainless-steel lines installed directly above cooking appliances and exhaust hoods, delivering the wet chemical agent (typically potassium carbonate) released by the UAE fire suppression system.

This agent targets high-risk zones such as fryers, grills, and cooktops, rapidly cooling surfaces and creating a protective barrier that prevents re-ignition — fully compliant with Dubai Civil Defence restaurant standards.

Fire suppression agent targets fire risk zones like fryers, grills, and cooktops, cooling surfaces and forming a barrier to prevent re-ignition — a process that complies with the DCD Approval for Restaurants in Dubai.

3- Fire Suppression System Control Panel

The control panel manages the entire restaurant fire suppression sequence, processing signals from the fire detectors, then it coordinates suppression agent discharge, fuel shutoff, and alarm activation. It also logs system activity for compliance audits and maintenance tracking which are essential for DCD Approval.

Common types of Restaurant Fire Suppression Systems

Common types of restaurant fire suppression systems include wet chemical, dry chemical, water mist, foam-based, and CO₂ systems — each designed for specific fire risks and kitchen environments.

To meet fire safety demands of commercial kitchens, restaurants must install fire suppression systems that are both effective and compliant with Dubai Civil Defense standards depending on the cooking environment and safety requirements.

Wet chemical systems are the standard for kitchens with fryers and grills as they’re specifically designed to handle grease fires and meet Dubai Civil Defence (DCD) and UL300 compliance.

Other systems –like dry chemical, water mist, foam-based, and CO₂ – serve different purposes and are used in specialized zones or non-cooking areas.

Here is a breakdown of each system, its applications, and its suitability for restaurant use under DCD regulations:

1- Wet Chemical Systems (DCD and UL300 Compliant)

wet chemical fire suppression system are the most widely used (or standard) systems in commercial kitchens as they use wet chemical systems that are specifically designed to suppress Class K fires like oil and grease fires using potassium-based agents (such as potassium carbonate) through pipes and nozzles installed in the hood and over cooking equipment, and shutting off gas lines at the same time.

This restaurant fire suppression system is required by Dubai Civil Defence (DCD) for kitchens using fryers, grills, and oil-based cooking.

Daem Contracting Company provides DCD-approved wet chemical systems tailored for restaurant environments.

2- Dry Chemical Systems

Dry Chemical fire suppression systems use powdered agents like monoammonium phosphate to interrupt the chemical reaction of fire.

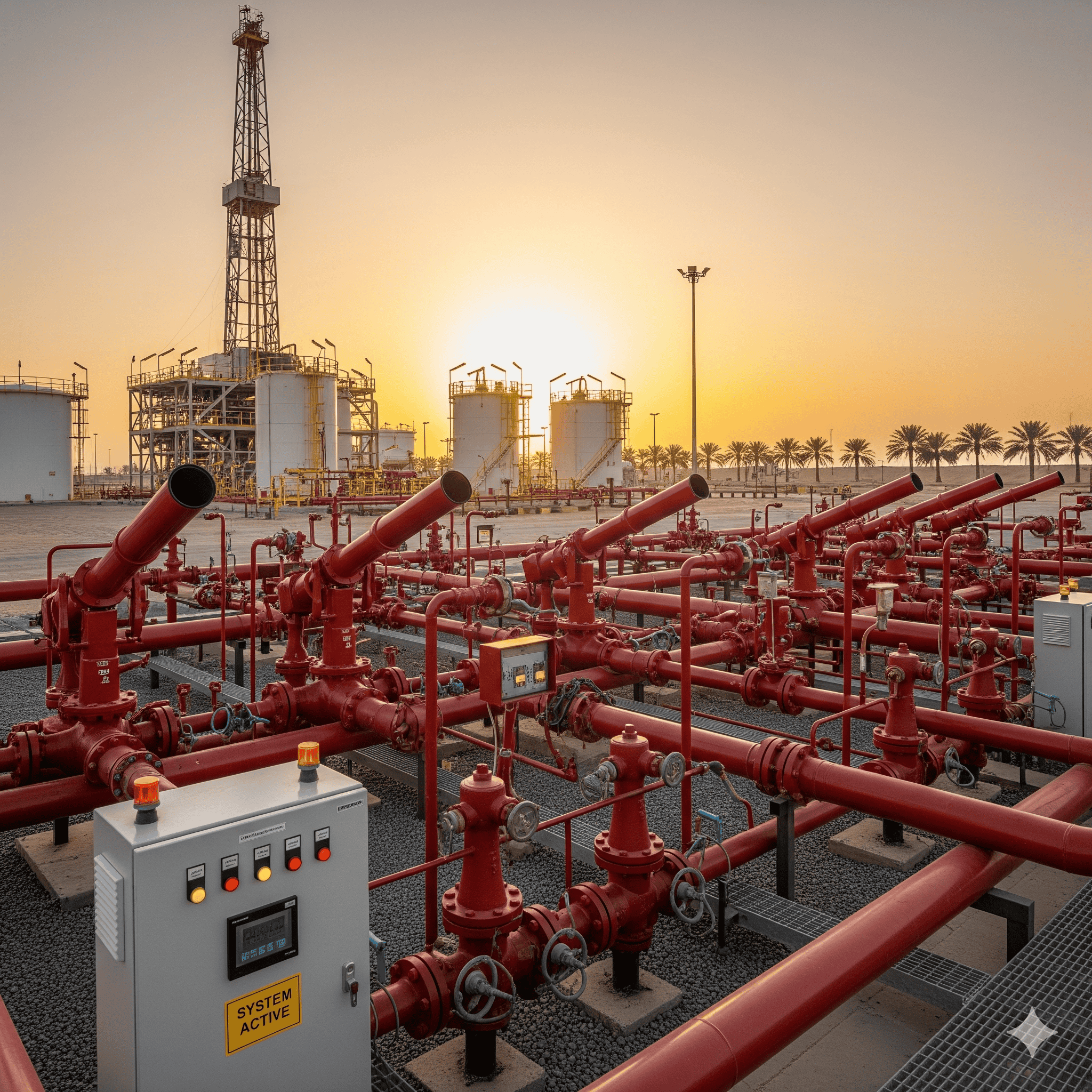

They are effective for Class A, B, and C fires, but they are less suitable for grease fires and are typically used in the Oil and Gas Industry,or non-cooking zones. They are generally not recommended for restaurant kitchens under DCD regulations.

3- Water Mist Systems

Water mist systems release ultra-fine droplets that cool flames and reduce oxygen concentration. They are ideal for kitchens with sensitive electrical equipment or open prep areas, as they leave minimal residue. Also, they can be used in combination with wet chemical systems for hybrid protection.

4- Foam-Based Systems

Foam Fire Suppression Systems deploy Aqueous Film-Forming Foam (AFFF) to blanket flammable liquids and prevent vapor release. These systems are commonly applied in specialty kitchens or food processing areas with fuel storage. However, they require thorough cleanup and are not typically recommended for grease-heavy environments.

5- Manual Pull Station Systems

MPS systems are mechanical triggers installed near kitchen exits, allowing staff to manually activate the suppression system if a fire is detected before automatic sensors respond.

DCD regulations require manual activation points as a backup safety measure in all commercial kitchens.

Legal Requirements for Restaurant Fire Suppression Systems in Dubai

In Dubai, all commercial kitchens are legally required to install automatic kitchen hood fire suppression systems approved by the Dubai Civil Defence (DCD) and international standards such as UL300 and NFPA 96.

These fire suppression systems are specifically designed to suppress Class K fires caused by cooking oils and fats, and must use approved Emirates Authority for Standardization and Metrology (ESMA) wet chemical agents, like stainless steel nozzles covering all cooking surfaces, automatically shut off gas and electricity upon detection, and integrate with exhaust fan shutdown.

Fire system installation must be carried out by DCD-certified contractors, and ongoing compliance requires Annual Maintenance Contracts (AMCs), periodic inspections, proper documentation to obtain and renew occupancy permits.

For DCD-approved solutions tailored to restaurant environments, Daem Contracting LLC offers expert installation and maintenance services that align with all regulatory requirements.

Mandatory Compliance Standards

To meet legal and safety requirements issued by NFPA 96 UL300 and Dubai Civil Defence, every commercial kitchen must follow specific fire suppression regulations. These include using DCD-approved systems such as wet chemical systems for grease fires, proper ventilation controls like exhaust hoods and grease filters, routine inspections which should be done at least every 6 months, and staff training in case of fire.

The table below outlines the key standards that restaurants must comply with to operate safely and stay certified:

Regulation | Requirement |

DCD code | All commercial kitchens must install approved fire suppression systems (wet chemical systems) integrated with ventilation and fuel shutoff mechanisms. |

UL 300 Certification | Systems must use wet chemical agents specifically designed for Class K fires (grease and oil). |

NFPA 96 Alignment | Kitchens must comply with ventilation control and kitchen fire protection standards, including hood and duct maintenance. |

Routine Inspections | Semi-annual inspections by DCD-approved technicians are mandatory to maintain operational certification. |

Manual & Automatic Activation | Systems must include both automatic heat detection triggers and manual pull stations for ultimate protection. |

Staff Training & Documentation | Kitchen staff must be trained to operate the system efficiently in case of fire, and documentation must be available for audits. |

Non-compliance can result in fines, operational shutdowns, or delays in obtaining a food establishment license. DCD must approve all installations as they must meet both local and international standards.

The Proper Installation for Commercial Kitchen Fire Suppression Systems

Installing a fire suppression system in a commercial kitchen isn’t just about meeting Dubai Civil Defence, NFPA 96, and UL 300 codes, it is about ensuring fast, reliable fire protection where fire risks –such as grease buildup in hoods which is highly flammable source, open flames like gas stoves, and worn wiring or overloaded circuits in ovens– are at highest.

To achieve this, restaurant fire suppression systems must be correctly placed and installed, fully integrated with ventilation and utility controls (like exhaust hoods, grease filters, and gas shutoff valves), and tailored to the kitchen’s layout and equipment. For example, island-style kitchens require 360 degree nozzle coverage and extended piping runs, while compact kitchens use low-profile hoods and tightly grouped sensors to avoid false alarms.

The following points outline what proper installation that comply with NFPA 96, UL 300, and DED regulations looks like in practice:

- Use only UL300-listed equipment and wet chemical agents specifically formulated for Class K fires involving cooking oils and fat.

- Position nozzles according to manufacturer schematics, avoiding dead spots or obstructed discharge paths..

- Integrate the system with hood and duct ventilation, the building’s fire alarm panel, and automatic shutoff mechanisms for gas and electricity.

- Verify coverage for specialty appliances such as woks, grills, and deep fryers, which may require additional nozzles or custom configurations.

- Maintain clear zones around discharge points, making sure nozzles are not blocked by equipment.

- Ensure exhaust and make-up air systems are properly balanced and compliant with ventilation codes to support fire containment and smoke removal.

- Mount manual activation stations in accessible, code-approved locations near kitchen exits to allow staff to activate the system in case of early fire detection.

Operational Training and System Documentation

Kitchen staff must be trained on manual activation –like where to locate and pull the manual activation station (near the kitchen exit) or fire hazard drills–, emergency response protocols such as a step-by-step fire response plan including fire suppression activation, evacuation through designated routes, and assisting others if safe. Also, post-fire procedures like securing the area and notifying management, Dubai Civil Defence, and documenting the accident.

Written instructions in case of fire –color-coded and translated into multiple languages like Arabic and English– should be posted in the kitchen (such as activation steps, evacuation routes, and emergency contacts) near all pull stations and training documentation which include course outlines, assessment results, and renewal date, should be maintained for compliance with insurance, licensing, and fire code audits.

Required documentation include:

1- System as-built drawings and serial numbers

Detailed as-built and component IDs help verify installation layout, support future servicing, and confirm system authenticity during inspection.

2- Inspection and maintenance logs (typically retained for 3 years).

Logs of routine checks, pressure readings, and technician reports –typically retained for at least three years– provide proof of ongoing compliance and readiness for insurance or licensing audits.

3- Maintenance tags affixed to all suppression cylinders.

Dated maintenance labels affixed to each suppression cylinder show the last maintenance visit and upcoming inspection schedule, offering quick visual confirmation during field checks.

Maintenance Schedule and Activities

Regular maintenance is essential for fire suppression system reliability and legal compliance, routine maintenance is not optional to ensure continued compliance and reliable system performance, commercial kitchens. These activities go beyond basic inspections and are essential for keeping the system pressurized, responsive, and compliant with inspection standards.

Below is what every commercial kitchen must regularly check to stay operational and audit-ready:

- Testing activation and detection devices to confirm that heat sensors and triggers like manual pull stations respond correctly under simulated fire conditions to ensure timely system activation.

- Cylinder pressure and expiry checks to verify that fire suppression agents are within pressure range –between 175 to 250 psi– and not expired (typically 5 to 12 years), ensuring readiness for discharge.

- Visual and physical confirmation of nozzles and lines avoiding blockages, leaks, or misalignments in the stainless steel piping or the discharge nozzles that could impair coverage or flow.

- Confirmation that shutoff devices function with the system properly ensuring control panel, gas valves and electrical interlock cutoffs activate in sync with the suppression system to eliminate fuel sources and prevent re-ignition.

- Replacement of the agent or system recharge after any discharge or event to restore full operational capacity and maintain compliance with Dubai Civil Defence and UL 300 standards.

- Updating inspection tags and submitting reports to authorities, maintaining audit-ready documents for licensing, insurance, and occupancy approvals.

Failure to perform regular inspections or maintenance is not only a code violation, but also invalidate insurance coverage and compromise liability protection in the event of a fire loss.

Routine Maintenance Schedule for Restaurant Fire Suppression Systems

To maintain compliance with Dubai Civil Defence regulations, commercial kitchen fire suppression systems must follow a structured maintenance schedule. The table below outlines key activities and their recommended frequencies based on NFPA 96 guidelines and industry best practices:

Activity | Recommended Frequency |

certified inspection to verify system compliance | Every 6 months |

Fusible link replacement to ensure reliable heat-triggered activation | At inspection, or as specified |

Full hydrostatic system testing under simulated stress conditions | Every 12 years |

In-house visual checks to spot issues like nozzle blockage or tag expiration | monthly |

hood/duct cleaning to prevent ignition or suppression coverage | 1-12 months (risk and use dependent) |

Appliance and hull cleaning to prevent fire spread around cooking equipment | daily/weekly (after heavy use) |

Commercial Kitchen Fire Safety Market: Insights & Top Suppliers

The global demand for restaurant fire suppression systems continues to grow steadily, driven by stricter safety regulations, smarter technologies, and focus on sustainability.

Leading manufacturers such as ANSUL, Amerex, Halton, Koetter Fire, Marlowe Fire & Security, and Reaction offer UL300-certified wet chemical systems designed for fast installation and low-maintenance operation.

Recent advancements include hybrid suppression models, real-time system monitoring capabilities, and integrated system control panels that help kitchens resume operations quickly after a fire hazard.

To meet compliance and performance benchmarks, every fire suppression systems must include the following Dubai Civil Defence and NFPA 96-approved core procedures:

Requirement | Explanation |

Wet Chemical Agent | For cooking surfaces and grease |

Automatic/Manual Activation | Both must be present |

Detectors In Hood/Duct | Detects heat/fire in appliances |

Fuel/Power Shutoff | Prevents fire fuel re-ignition |

System Maintenance | Must be by certified people |

Documentation | Inspection tags, records kept |

Hood Cleaning | Grease removal per schedule |

Staff Training | On system operation and evacuation |

Conclusion: Key Points and Next Steps for Restaurant Owners

Restaurant owners must go beyond installation to stay compliant and protect their business, because fire suppression systems require strategic integration that is embedded into the kitchen’s operational and safety infrastructure and routine maintenance like weekly checks or semi-annual inspections to make sure the system remains responsive and compliant over time.

The following key actions guarantee your kitchen remains safe, inspection-ready, and digitally transparent for regulators, insurers, and customers.

- Integrate your restaurant suppression system fully with your hood, ventilation, alarm panel, and utility shutoff controls in order to coordinate fire containment by triggering suppression, airflow control, and fuel cutoff simultaneously.

- Commit to semi-annual professional inspections and cleaning as required by Dubai Civil Defence and NFPA 96, and immediately review your system if appliances change to Maintain system reliability, ensure coverage accuracy, and fulfill legal maintenance requirements.

- Regular staff training and clear kitchen procedures such as routine fire response drills and posted emergency protocols can equip personnel to act quickly and effectively during fire events, minimizing risk to life and property.

- Optimize your restaurant’s digital presence by ensuring your safety protocols, system specifications, and compliance certificates are up-to-date, easily accessible, and well-documented for inspections, insurance, and customer assurance by demonstrating operational transparency and readiness.

Implementing best practices in fire suppression not only protects your restaurant, guests, and community –not only from physical damage, but operational, legal, and reputation as well, it also preserves your brand, regulatory compliance, and business continuity.

Frequently Asked Questions:

1- How much does a restaurant fire suppression system cost?

Costs vary depending on kitchen size, system type, and regional service rates. Based on user reports from Reddit:

- Routine service and inspection: about $260 every 3 months.

- CO2 recharge for a 4-gallon system: about $195 per refill.

- Complete system replacement (2 units): almost $5000 in a high-cost area.

- Hood suppression redesign (12-foot hood): about $4200.

- High-end installations (e.g. 16-foot hood with HVAC): between $40,000 and $60,000

2- Can I install a used fire suppression system to save money?

Yes, but this approach carries risks. UL 300 or Dubai Civil Defence compliance, warranty coverage, and code approval may be compromised. Always consult a certified installer before purchasing secondhand equipment.

3- What do I need to do if I change appliances or move kitchen equipment?

Any change requires review and possibly redesign of the the fire suppression system by a certified professional to maintain code compliance and insurance coverage.

4- How should I train my staff on fire suppression use?

Staff must receive training at hire and annually on how to manually pull the suppression system, emergency shutdown procedures, and safe evacuation. Post instructions clearly and conduct regular fire drills.

5- Is Restaurant Approval mandatory before opening a restaurant in Dubai?

Yes, Restaurant Approval in Dubai is mandatory. Without it, the restaurant cannot legally operate, obtain final licensing, or open to the public.

Comments are closed