Have you ever wondered how a mobile fuel station or a temporary construction site can combat a fire without endangering lives or damaging equipment?

The answer lies in mobile fire suppression systems — an innovative solution that combines early detection, instant alerts, and automatic extinguishing using foam, dry powder, or clean agents to ensure swift and effective protection under any circumstances.

In this article, we’ll take you on a comprehensive tour of everything you need to know about this vital system:

From its components and how each part functions, to a step-by-step explanation of its immediate response mechanism, from key differences between mobile and traditional systems and the most effective extinguishing agents, to maintenance strategies that ensure continuous readiness.

and finally, the importance of complying with international and local standards while training personnel to operate the system safely and efficiently.

Get ready to discover the technology, safety, and flexibility that enable mobile stations to combat fires with confidence and professionalism — wherever they are, with DAEM CONTRACTING!

Table of Contents

What is a Fire Suppression Systems for Mobile Stations?

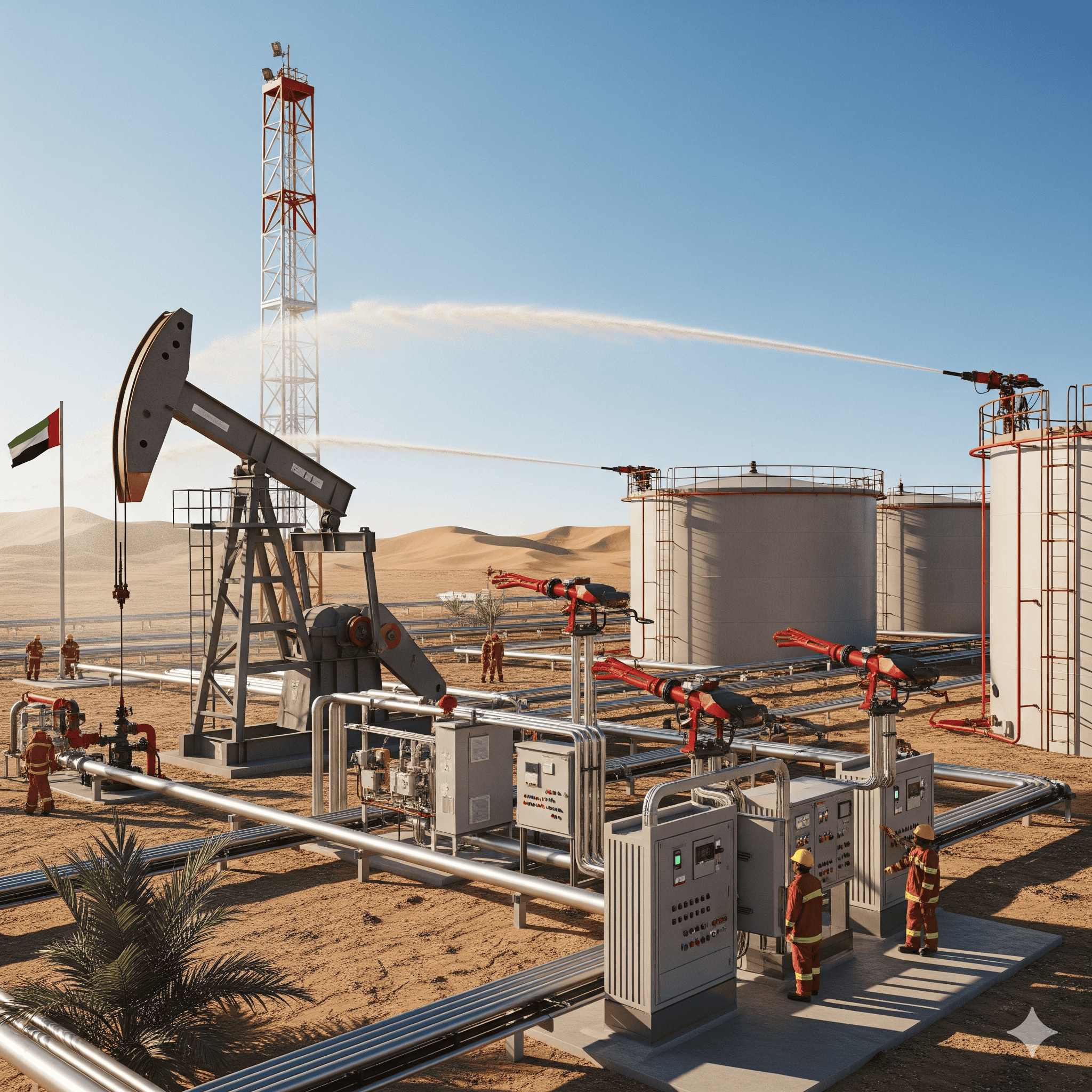

Fire Suppression Systems for Mobile Stations is an automated system specifically designed to extinguish fires in temporary or mobile facilities such as mobile fuel stations, field operation centers, oil drilling platforms, construction sites, and temporary industrial facilities.

This system primarily relies on the use of chemicals, foam, or gases such as carbon dioxide. It is characterized by sensory detectors that identify the location of the fire and automatic release mechanisms that address it immediately.

This ensures a rapid and effective response without the need for direct human intervention, distinguishing it from traditional fixed systems typically associated with permanent structures.

💡 Ensure safety for mobile and temporary facilities with advanced Fire Suppression Systems for Mobile Stations.

Trust a professional fire protection company in Dubai, DAEM, to deliver complete Fire Systems Services and Solutions, combining speed, reliability, and automated fire control.

What are the Components of a Mobile Fire Suppression System?

A mobile fire suppression system consists of an advanced detection and control unit, such as smoke and heat detectors, connected to a suppression agent release system that includes storage cylinders, discharge valves, piping networks, and nozzles.

It is also supported by an alert and notification unit with audible and visual devices for early warning, along with power sources to ensure continuous operation. Finally, safety components such as control switches guarantee the system’s secure and reliable functioning, providing a rapid and effective response suited to mobile operating environments—particularly in mobile fuel stations and temporary industrial facilities—as outlined below:

1. Detection and Control Systems: The nerve center of the station, responsible for detecting fires and issuing operational commands. It includes:

Smoke and Heat Detectors: Electronic devices that detect flames, smoke, or abnormal temperature increases, automatically activating the system at an early stage.

Control Panels: Act as the system’s brain, receiving signals from detectors and automatically triggering the suppression process while monitoring system status and displaying faults.

Manual Release Stations: Allow operators to manually activate the system in case of automatic failure or when direct control is desired.

2. Suppression Agent Release System: Stores and releases extinguishing agents when needed. It consists of:

Storage Cylinders/Tanks: Contain suppression agents, which may be:

Gaseous (e.g., FM-200, NOVEC 1230, CO₂) for areas with sensitive equipment.

Liquid (e.g., AFFF foam solution) for flammable liquid fires.

Dry Chemical Powder for varied fire types.

Release Valves: Control the discharge of the suppression agent from cylinders or tanks when needed. These operate electrically (solenoid valves) or mechanically.

Piping Network and Nozzles: Distribute the gaseous or liquid suppression agent evenly and at appropriate pressure to the target area.

3. Alarm and Notification Systems: Alert personnel before suppression activation:

Audible and Visual Alarms: Emit warnings (sirens and lights) to alert onsite personnel before agent discharge, allowing time for evacuation. This component is critical in gas-based systems to avoid suffocation risks.

4. Power Sources: The electrical supply system ensures continuous operation under all conditions:

Primary and Backup Power: Ensures system functionality during main power outages. The system typically relies on a primary source (mains electricity) and a backup (batteries) to power the control panel and detectors.

5. Additional Safety Components: Auxiliary safety features ensure secure and reliable operation:

Control and Safety Switches: Such as pressure switches that confirm system activation.

Abort Switch: Used to cancel system activation after a warning alarm and before agent discharge in case of accidental activation or if the fire is manually controlled.

Safety Valves/Burst Discs: Protect cylinders from overpressure that could lead to explosion.

Mounting Framework: A sturdy structure and support to securely fasten all components during transport and movement, continuing to provide clear, structured, and technically accurate translations as per the user’s detailed request.

💡 Protect your mobile stations and facilities with top-tier fire alarm systems in the UAE. Explore types, components, compliance requirements, and professional installation services today—ensure safety, reliability, and peace of mind.

How Does a Mobile Fire Suppression System Work?

Mobile Fire Protection Systems operates through smoke and heat detectors that send signals to a central control panel. Upon confirming a fire, suppression protocols are automatically activated, triggering audible and visual alarms, disconnecting electrical loads, shutting down ventilation systems, and finally releasing extinguishing agents such as foam through a hydraulically designed network of pipes and nozzles to fully cover the hazard area.

A programmed time delay typically precedes the agent release, providing individuals time to evacuate, as follows:

Detection: Continuous monitoring by smoke and heat detectors captures initial signs of fire.

Verification & Activation: The control panel analyzes signals to avoid false alarms, then issues activation commands including:

Activating audible/visual alarm devices.

Automatically disconnecting electrical circuits.

Preparing cylinder release valves for activation.

Delay Time: A programmed interval (typically 20–30 seconds) allows for area evacuation or activation of an abort switch.

Discharge: Release of the extinguishing agent (Clean Agent / Foam / Water Mist) through engineered nozzles that ensure even distribution, effectively reducing heat or halting the fire’s chemical reaction.

How Do Mobile Fire Suppression Systems Differ from Traditional Protection Systems?

Mobile systems differ from traditional ones in their portability and reliance on specialized extinguishing agents such as foam or dry powder, whereas traditional systems, including a Fire Suppression System for Buildings, are fixed and integrated into the infrastructure, typically using water.

In terms of cost, mobile solutions are less burdensome as they require no complex structural preparations, in addition to offering high flexibility to adapt to multiple sites or changing conditions. Fixed systems, on the other hand, are designed for permanent buildings and facilities such as factories. They operate efficiently within a predefined scope but are less flexible and more costly.

The following table highlights the key differences between the two systems:

| Aspect | Traditional Systems | Mobile Systems |

|---|---|---|

| Installation Type | Fixed and integrated into the building | Portable and redeployable |

| Extinguishing Agents | Water / gases (in advanced systems) | Foam / dry powder / specialized chemicals |

| Deployment Time | Immediate | Immediate |

| Initial Cost | Higher | Relatively lower |

| Application Areas | Permanent buildings / fixed facilities | Temporary / remote / mobile sites |

💡 Ensure safety in high-risk environments with Fire Suppression for the Oil and Gas Industry from DAEM Fire Fighting Contracting Company, providing fast, automated, and reliable fire protection.

Types of Fire Suppression Agents Used in Mobile Stations and Their Mechanisms

Fire suppression agents in mobile stations vary depending on the type of fire. Dry powders interrupt the chemical reaction and smother flames, while foam cools surfaces and forms an insulating layer to prevent reignition. Wet chemicals are used for oil and grease fires, as they cool the oil and create a protective membrane.

On the other hand, clean agents such as FM200 and Novec 1230 act rapidly by absorbing heat without leaving residues, making them suitable for sensitive equipment. CO₂ and nitrogen reduce oxygen levels to prevent combustion, though CO₂ is unsuitable for occupied areas. Finally, aerosol agents are effective in small, enclosed spaces but require ventilation after use.

Foam: Isolates oxygen by covering the burning material with a foam layer that absorbs heat due to its water content.

Applications: Flammable liquid fires (Class B), such as fuels and oils.

Advantages: Effective at smothering fires and preventing reignition.

Disadvantages: May cause environmental contamination and require cleanup after use.

Dry Chemical Powder: Interrupts the chemical chain reaction of combustion and covers fuel to isolate it from oxygen.

Applications: Versatile fires (Class A, B, C), including electrical and flammable liquid fires.

Advantages: Rapid dispersion and broad coverage.

Disadvantages: Leaves difficult-to-clean residues and may damage sensitive electronic equipment.

Clean Agents (e.g., FM200, Novec 1230): Absorb heat and disrupt the chemical reaction of combustion without consuming oxygen or leaving residues.

Applications: Areas with sensitive equipment, such as server rooms and data centers (Class A, B, C fires).

Advantages: Do not harm electronic equipment and act quickly.

Disadvantages: High cost and require precise storage and release systems.

Carbon Dioxide (CO₂): Smothers fires by reducing oxygen concentration in the surrounding area to below 15% (the level required for combustion).

Applications: Electrical and flammable liquid fires in unoccupied areas.

Advantages: Leaves no residues and disperses quickly.

Disadvantages: Poses a suffocation risk to humans and is unsuitable for occupied spaces.

Nitrogen (N₂): Lowers oxygen concentration to levels that cannot support combustion (below 15%) without endangering humans when used in controlled concentrations.

Applications: Fire prevention in industrial facilities and suppression of electrical equipment fires.

Advantages: Inert and environmentally safe.

Disadvantages: Requires precise injection and concentration monitoring systems.

Aerosol: Releases fine particles to absorb heat and disrupt the chemical reaction of combustion.

Applications: Confined and enclosed spaces, such as electrical and generator rooms.

Advantages: Effective in small areas and easy to store.

Disadvantages: May impair visibility during operation and requires ventilation after use.

Wet Chemical: Cools the surface of oily layers and forms a foam-like substance to isolate oxygen.

Applications: Oil and grease fires in restaurants and commercial kitchens (Class K).

Advantages: Specifically designed for cooking fires and reduces reignition risks.

Disadvantages: Limited application and unsuitable for most other fire types.

Strategies for Ensuring Long-Term Effectiveness of Mobile Fire Suppression Systems in the UAE

To ensure the long-term effectiveness of fire suppression systems in mobile stations, an integrated approach must be adopted. This includes professional installation in accordance with the UAE Fire and Life Safety Code and international standards such as NFPA.

Conducting semi-annual and annual maintenance by certified technicians, along with system testing and part replacements as needed, is fundamental to maintaining operational readiness.

Additionally, it is recommended to integrate the system with early detection technologies such as smoke and heat detectors, train personnel on system operation and safe evacuation procedures, and ensure that the system design and coverage are appropriate for the specific risks of each mobile station.

💡 Protect your facilities with Wireless Fire Alarm Systems in the UAE from DAEM, a trusted fire safety company, offering fast, reliable, and fully compliant solutions for mobile and permanent sites.

1. Professional Installation Requirements for Mobile Station Fire Suppression Systems

Installing a Fire Safety System for Mobile Units requires precise site assessment and engineering design by certified experts such as DAEM CONTRACTING COMPANY, in compliance with NFPA standards and local fire safety codes.

The installation process involves accurate positioning of detectors and nozzles, secure mounting of pipes and connections, proper electrical wiring, and thorough testing of tank pressure and pumps. Comprehensive operational testing must follow installation to ensure full system readiness and effectiveness during emergencies.

- Site Assessment: Conduct a thorough study to determine the mobile station’s layout, locations of critical equipment, fuel sources, flammable materials, and areas where people gather. This includes identifying potential hazard zones and developing a plan for complete coverage.

- Specialized Engineering Design: Collaborate with safety experts to design a customized system for each station, ensuring optimal placement of detectors and nozzles, selecting the most suitable extinguishing agents, and determining pipe routes and operating pressure based on the station’s size and area.

- Compliance with Standards: Ensure all system components meet the UAE Fire and Life Safety Code, international NFPA standards, and other local regulations to guarantee legal compliance and operational safety.

- Component Preparation: Install all essential elements including control panels, heat and smoke detectors, audible and visual alarm devices, and extinguishing agent distribution equipment such as nozzles, pipes, and tanks.

- Detector and Nozzle Placement: Carefully position detectors and nozzles in high-risk areas like fuel sources and electrical equipment, considering potential obstructions to ensure rapid and effective response.

- Piping Network and Installation: Install pipes and connections according to safety standards, conducting pressure tests to check for leaks and ensure efficient delivery of extinguishing agents.

- Electrical Connections: Connect all electrical components, including manual activation stations, ensuring proper wiring installation, secure fastening, and testing to prevent short circuits or open connections.

- Pressure and Level Checks: Verify tank and pump pressure, along with fluid or chemical levels, to ensure system readiness without malfunctions when needed.

- System Testing: Conduct comprehensive operational tests to verify the performance of all components, from fire detection and alarm activation to extinguishing agent release.

- Inspection and Documentation: Complete all inspection and certification reports, ensuring warranty validity and documenting system status before handover to operations.

- Periodic Maintenance: Schedule semi-annual and annual inspections to verify component integrity, fluid levels, tank pressure, and detector/nozzle performance, ensuring continuous readiness and effectiveness.

2. Periodic Maintenance Program for Mobile Station Fire Suppression Systems

The periodic maintenance program for fire suppression systems in mobile stations includes daily and weekly procedures such as system pressure checks to ensure readiness, along with monthly maintenance involving pump operation, power source inspections, and component cleaning.

Meanwhile, annual maintenance involves refilling or replacing extinguishing agents, hydraulic pressure testing, and detector calibration to ensure year-round performance accuracy and system reliability, as follows:

🔹 Daily/Weekly Maintenance:

Pressure checks in gas cylinders or foam tanks

Verification of unobstructed nozzles and piping

Control panel and sensor testing

🔹 Monthly Maintenance:

Water and foam pump testing

Inspection of primary and backup power sources

Cleaning of nozzles and sprinklers from dust and debris

🔹 Annual Maintenance:

Refilling or replacement of suppression agents (such as foam or dry chemical powder)

Hydraulic pressure testing of pipes and tanks

Calibration of sensors and detection devices

This comprehensive maintenance program ensures continuous system reliability and compliance with UAE fire safety regulations and international standards.

3. Why Compliance with UAE Fire Code and NFPA Standards is Crucial for Mobile Station Fire Suppression Systems

Compliance with the UAE Fire Code and NFPA standards is essential for Temporary Site Fire Suppression Systems to ensure the safety of lives and property, meet legal requirements, build industry trust, and maintain business continuity by avoiding penalties and operational disruptions. Adherence to these international frameworks provides a unified approach to fire prevention and response, reduces risks, and supports the UAE’s vision of safe and sustainable cities.

- Regulatory Compliance: UAE Civil Defence mandates adherence to NFPA standards, making them a legal requirement for fire protection systems.

- Life and Property Safety: Compliance ensures the design and installation of effective systems to protect individuals and minimize potential fire damage.

- Unified Safety Standards: NFPA standards provide a global framework to ensure system consistency and reliability regardless of location.

- Business Continuity: Compliance measures help minimize operational downtime and losses following any fire incident.

- Industry Trust and Reputation: Compliant systems reflect reliability and safety, enhancing confidence among insurers, tenants, and authorities.

- Risk Reduction: Implementing approved guidelines helps reduce fire-related incidents and ensures effective response when they occur.

- Support for National Vision: Compliance supports the UAE’s strategic goal of creating safe and sustainable urban environments through effective protection measures.

- Avoidance of Penalties: Non-compliance may result in significant fines, operational shutdowns, and rejected insurance claims, making compliance a strategic investment.

4. Why Personnel Training is Essential for Safe and Efficient Operation of Fire Suppression Systems

Technical training for personnel is a critical requirement to ensure the effectiveness of fire suppression systems. It enables individuals to respond rapidly and accurately during emergencies and helps reduce human and material losses, as follows:

☑︎ Operational Efficiency: Familiarity with system operations (such as FM200, foam, and dry powder systems) and precise response within 120 seconds of fire detection.

☑︎ Preventive Maintenance: Ability to detect early malfunctions, such as low cylinder pressure or clogged nozzles, and document reports in accordance with NFPA standards.

☑︎ Integration with Safety Systems: Coordination of evacuation procedures with the operation of ventilation and automatic shutdown systems to limit smoke spread.

☑︎ Regulatory Compliance: Adherence to requirements set by the National Emergency Crisis and Disaster Management Authority and UAE Civil Defence regulations.

This training transforms personnel from mere operators into effective components of the overall safety system, reducing response times to less than 60 seconds in critical situations.

◊ Conclusion ◊

This article has demonstrated that a fire suppression system for mobile stations is far more than just equipment and piping—it represents a comprehensive solution integrating intelligence, immediate response, and practical flexibility to protect lives and property in dynamic and temporary environments.

By understanding its components, operational principles, appropriate suppression agents, and the critical importance of regular maintenance and compliance with international standards, any mobile station can be fully prepared to confront fire incidents with confidence and efficiency.

Investing in such systems and providing proper personnel training not only safeguards equipment and operations but, more importantly, ensures human safety and business continuity. This makes it a strategic and essential choice for any mobile facility committed to achieving the highest levels of safety and professionalism.

Frequently Asked Questions about Fire Alarm Systems

1- What’s the fastest and cleanest fire suppression agent for small mobile units (e.g., trailers, food trucks)?

The fastest and cleanest option for a fire suppression system for a food truck is a clean agent like FM-200 or Novec 1230. These agents suppress fires within seconds, leave no residue, and are safe for use around people and electronics—making them ideal for compact mobile setups. For grease fires in kitchens, a wet chemical system is often required as a complement.

2. How do you prevent false alarms, especially due to vibration, dust, or heat fluctuations in mobile stations?

To prevent false alarms in a fire suppression system for mobile stations, use vibration- and dust-resistant sensors with adjustable heat thresholds. Proper sensor placement and regular calibration ensure reliable detection without unnecessary triggers.

3. What is the typical lifespan of a mobile suppression system and how often should components be replaced or tested??

The typical lifespan of a fire suppression system for mobile stations is 10–15 years, depending on usage and environmental conditions. Key components such as cylinders, valves, and sensors should be inspected and tested annually, while some consumables like gas or foam may require refill or replacement every 5–7 years to ensure full operational readiness.

4.What safety measures are needed to avoid danger to humans during agent discharge (especially for gas-based or CO₂ systems)?

For a fire suppression system for mobile stations, ensure proper safety by:

Installing audible and visual alarms to warn occupants before discharge.

Providing time delays to allow evacuation.

Using clean agents safe for occupied spaces, while CO₂ systems should only operate in unoccupied areas.

Training staff on emergency procedures and manual override switches to prevent accidental exposure.

M. Hussam Almahmoud

Business Owner | DAEM CONTRACTING LLC Dubai

M. Hussam Almahmoud Graduated From Aleppo University BSC in Mechanical Engineering, CEO and partner In White Eagkes Hen trd ( established in 2005 , White Eagle Transport Est 2008 , City care Fire Est 2010 , Daem Contracting Est 2014 , Abraj Wa Mabani cont Est 2016 , White eagles gen trd LTD Est 2021 in Manchester UK , Partner in ICE Elektronik Dis Ticarat limited Sirketi Istanbul turkey

Comments are closed