In today’s high-risk environments, a fire protection system is more than a technical feature—it’s a frontline defense. Designed to detect fire early and respond automatically, this suppression system prevents escalation and minimizes damage.

From residential towers to data centers and industrial facilities, a reliable fire safety system protects lives, assets, and operational continuity—combining advanced engineering with safety.

At Daem Contracting Company, we deliver fully integrated automatic fire control systems across the UAE.

Table of Contents

What Is a Fire Suppression System And How Does It Function?

A fire suppression system is an automatic, pre-engineered solution designed to detect and extinguish fires in their critical early stages—or at the very least, control their spread—using specialized extinguishing agents such as gases, foam, water mist, or dry chemicals.

Unlike standard fire systems that only provide warning, these systems take immediate action to protect lives, critical assets, and infrastructure from devastating damage. They are particularly vital in environments where a rapid manual response is unlikely or where traditional water sprinklers could cause severe collateral damage, such as in data centers, commercial kitchens, and industrial facilities.

How Does It Function?

A modern fire suppression solutions functions through a seamless, three-stage process engineered for speed and reliability:

Detection: Advanced sensors (detecting heat, smoke, or flames) continuously monitor the environment. Upon identifying a potential fire, they immediately send a signal to the control panel. This early action demonstrates the true fire suppression meaning in protecting people and assets.

Alarm & Activation: The system’s control panel, acting as the central brain, processes the signal. It first triggers audible and visual alarms to alert occupants to evacuate. It then activates the release mechanism, either automatically or via a manual emergency trigger. This makes the system more effective than a basic firefighting system that only alerts but does not act.

Suppression: The system releases the most suitable extinguishing agent through a network of pipes and discharge nozzles. The agent works by rapidly cooling the fire, smothering it to reduce oxygen, or disrupting the chemical combustion process, effectively suppressing the blaze before it can escalate.

Fire suppression systems and fire alarm installations both rely on strong design and seamless integration. Their effectiveness depends on how well the engineering, detection devices, and agent delivery are planned and executed.

What Are The Core Components Of The Fire Suppression System?

The key components of a fire fighting suppression system are detectors, which first sense the presence of a fire; the control panel, which then processes the signals and activates the system; suppression agents, such as water, foam, or gas, that effectively extinguish the flames; the delivery network, including pipes and nozzles, which ensures the agents reach the fire; notification devices, which alert occupants; and a reliable power supply, with backup, to maintain continuous operation.

These elements form the backbone of any fire protection system and can be divided into five core components:

1. Detection Devices (The Senses)

Function: These are the system’s “senses,” providing the crucial first alert. They continuously monitor the protected environment for the earliest signs of a fire—be it smoke, a rapid rise in heat, or flames.

For residential settings, such devices are essential in a home fire suppression system or even a residential fire suppression system where lives are at higher risk.

Key Elements: Includes smoke detectors, heat detectors (fixed temperature or rate-of-rise), and flame detectors. The type selected depends on the specific hazards and environment of the protected area (e.g., dusty industrial settings may require different detectors than a clean server room).

2. The Control Panel (The Brain)

Function: This is the system’s central processing unit. It receives signals from the detection devices, processes the information, and then executes a pre-programmed response. It first triggers alarms and then activates the release mechanism.

This highlights the difference between a regular panel and a fully engineered extinguishing system.

Key Elements: Provides 24/7 system monitoring, indicates status (Normal, Fault, Fire), performs self-diagnostics for wiring faults, and monitors the pressure and readiness of the suppression agent containers.

3. Suppression Agents & Containers (The Extinguisher)

Function: These are the substances that physically extinguish the fire. The agent is carefully selected based on the class of fire (e.g., electrical, flammable liquids) and the need to protect sensitive assets from damage.

Some systems even use compact, self-contained fire suppression system designs, such as a server cabinet unit that protects critical IT equipment without the need for extensive piping.

Key Elements: Agents are stored in pressurized cylinders or tanks. They are equipped with release valves (often electro-mechanical or triggered by pilot gas) and contain agents like clean gases (Novec 1230, FM-200), chemicals (dry or wet agents), foam, or water mist.

This wide range of fire suppression equipment ensures every hazard type can be managed effectively.

4. Delivery Network (The Arteries)

Function: This is the physical pathway that transports the suppression agent from its container directly to the seat of the fire with speed and precision.

Modern fire suppression system design ensures the piping and nozzles are strategically installed to maximize effectiveness.

Key Elements: A network of stainless steel or galvanized pipes, control valves to direct the flow, and discharge nozzles. Nozzles are strategically placed and engineered to ensure the agent is dispersed effectively and evenly throughout the protected zone.

5. Activation & Release Mechanism (The Trigger)

Function: This mechanism triggers the physical release of the suppression agent.

Key Elements: Activation can be:

Automatic: The primary method, initiated by an electrical signal from the control panel after confirmed detection.

Manual: Achieved via manual pull stations or abort buttons located at exits, allowing personnel to activate or halt the system in an emergency.

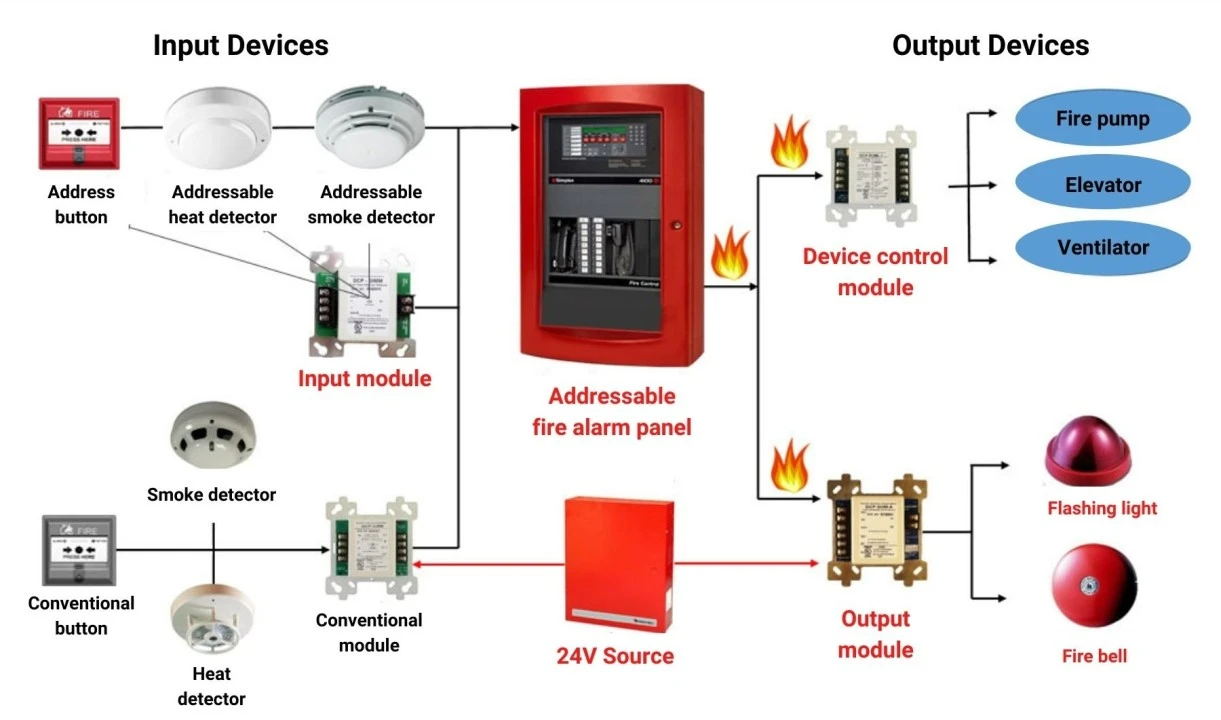

💡 The Difference Between Conventional and Addressable Fire Alarm Systems highlights the importance of integration: even the most advanced agent cannot act effectively without a smart control “brain” and a reliable delivery network. This coordinated design ensures a rapid, dependable, and precise response.

What Are Fire Suppression Agents?

The main types of fire suppression agents include water-based agents, which cool and smother fires; chemical agents, which interrupt the chemical chain reaction of combustion; as well as gaseous and clean agents, which reduce oxygen levels and leave no residue; in addition to foam agents, which smother flames and seal fuel surfaces; and finally aerosol suppression agents, which release fine chemical particles to inhibit the fire’s reaction.

Below are the primary categories of suppression agents used in modern fire protection systems:

1. Water-Based Agents

The most common and cost-effective agent, primarily effective by cooling the fire.

Standard Water: Used in sprinkler and deluge systems. Effective on Class A (solid combustibles) fires.

Water Mist: Ultra-fine water droplets that cool the fire more efficiently and, through rapid vaporization, smother it by displacing oxygen. Less water damage makes it suitable for a wider range of hazards.

Best For: General fire protection in offices, residential buildings, warehouses (Class A fires).

2. Chemical Agents

These agents extinguish fires primarily by interrupting the chemical chain reaction of combustion.

Dry Chemical: Powders (e.g., ABC: Monoammonium Phosphate, BC: Sodium Bicarbonate). Highly effective on Class A, B, and C fires. Can be corrosive and cause cleanup issues.

Wet Chemical: Specifically designed for commercial kitchen hood systems. They saponify—turning cooking fats into a soapy foam that blankets the surface, cooling and preventing re-ignition (Class K fires).

Best For: Industrial settings, commercial kitchens, flammable liquid areas (Class B/K fires).

3. Gaseous & Clean Agents

These agents work primarily by reducing oxygen levels to a point where combustion cannot be sustained (below 15%). They are ideal because they leave no residue, protecting sensitive equipment.

Inert Gases: Natural gases like Argon (Ar) and Nitrogen (N₂). They are naturally occurring, safe for people, and environmentally friendly but require large storage cylinders due to their low efficiency.

Synthetic Clean Agents: Chemicals like FM-200™ (HFC-227ea) and Novec™ 1230. Extremely effective, requiring much smaller storage space. They are designed to be safe for occupied spaces and leave no residue.

Carbon Dioxide (CO₂): A highly effective, inexpensive agent for unoccupied spaces. It works by oxygen depletion and poses a severe asphyxiation risk to humans.

Best For: Data centers, server rooms, archives, museums, control rooms, and any area with high-value, water-sensitive assets (Class A, B, and C electrical fires).

4. Foam Agents (Foam Concentrates)

Foam works by smothering the fire and sealing the fuel surface, preventing vapor release. It is mixed with water in specific proportions.

AFFF (Aqueous Film-Forming Foam): Forms a water-based film on flammable liquids, extinguishing the fire and preventing re-ignition.

Best For: Flammable and combustible liquid fires (Class B), such as in aircraft hangars, fuel farms, and industrial facilities.

5. Aerosol Suppression Agents

These are solid chemical aerosols that, when activated, release a fine mist of potassium particles that inhibit the chemical chain reaction of the fire.

How it works: The generator contains a solid propellant that undergoes a chemical reaction to disperse the aerosol agent.

Pros: Compact, requires no pressurized piping network.

Cons: Can produce minor residue and is not typically recommended for occupied spaces due to minor visibility obstruction.

Best For: Enclosed electrical panels, engine bays, wind turbines, and localized hazards.

What Is Fire Suppression System Release And How Does It Work?

The release mechanism in a fire suppression systems refers to the process by which extinguishing agents are deployed to suppress fire. This process typically follows one of the two primary methods: direct release or indirect release.

Direct release:

In the direct release system, a specialized heat-sensitive tube serves as both the detection and discharge mechanism.

When the ambient temperature at the fire source reaches a critical threshold (typically 90–100°C), the tube ruptures at its hottest point, triggering the immediate release of the suppression agent directly onto the fire.

- Ideal for small, enclosed spaces such as electrical enclosures, control panels, and industrial cabinets.

The Indirect Release

The indirect release system separates detection and discharge functions. The heat-sensitive tube detects elevated temperatures and signals a separate network of pipes and discharge nozzles connected to suppression agent containers. Upon activation, the agent is released through nozzles to cover a wider area.

- Suitable for larger or open environments such as server rooms, laboratories, or battery storage areas.

📌 To better understand the complete fire protection infrastructure, it’s important to differentiate between active systems that respond to fire, and passive systems that contain it.

Active vs. Passive Fire Protection: What’s the Difference and When to Use Each?

Both Active Fire Protection (AFP) and Passive Fire Protection (PFP) serve as fundamental factors of building’s fire safety. While active systems serve detecting and suppressing fires actively, passive systems aim to contain fire and smoke to prevent their spread. Together, they create a comprehensive defense that protects lives, property, and ensures evacuation time.

1- The Active Fire Protection System or APP

The active protection systems include electronic or mechanical components to detect, alert, and extinguish fires. These systems function automatically or manually and require regular inspection and maintenance.

The APP includes:

- Fire detection system (smoke sensors, heat sensors)

- Fire alarm system

- Fire suppression system

- Suppression agents ( water, chemicals, gas)

✅ Ensure fast fire response and protection by learning about the Essential Components of a Fire Alarm System before the fire grows.

2- The Passive Fire Protection System or the PFP

Passive systems are built into the structure of the building and do not require activation. Their role is to prevent fires from spreading, maintain structural integrity, and allow more time for evacuation.

PFP includes:

- Fire-rated walls, doors, ceilings, and floors

- Compartmentalization (dividing the building into sections)

- Fire-resistant coatings (intumescent paints)

- Firestops for cable and pipe penetrations

✅ Critical for long-term containment and meeting building code regulations, highlighting The Indispensable Role of Fire Alarm Systems in UAE Building Safety.

📌 At Daem Contracting LLC, we provide expert Fire Pump Repair in Dubai, ensuring all systems are fully operational and compliant with UAE Civil Defense standards.

Where Are Fire Suppression Systems Commonly Used?

Fire suppression systems are commonly used in homes and buildings, and they play a critical role in commercial kitchens as well.

They are also essential for mobile stations and food trucks, while across the oil & gas industry—including oil wells, remote storage, and large industrial sites—they provide advanced protection against high-risk fire hazards.

Fire Suppression Systems for Oil Wells & Remote Storage are designed to handle extreme fire hazards in remote oil facilities where rapid suppression is critical.

Fire Suppression Systems for Mobile Stations provide compact yet powerful protection against fires in mobile fuel and service stations.

Fire Suppression System for Buildings ensures occupant safety and regulatory compliance in residential, commercial, and high-occupancy structures.

Restaurant Fire Suppression System targets grease and cooking-related fires, protecting both staff and customers in dining facilities.

Fire Suppression for the Oil and Gas Industry addresses large-scale flammable risks, safeguarding pipelines, rigs, refineries, and processing plants.

Fire Suppression System for Food Trucks offers specialized solutions for confined cooking spaces where traditional methods may fail.

Fire Suppression Systems for Commercial Kitchens control grease fires with wet chemical agents, essential for hotels, malls, and catering facilities.

Fire Suppression System for Home delivers cost-effective safety for private residences, ensuring families are protected from sudden fire risks.

Why Choose a Fire Suppression System? Key Benefits

Fire suppression systems are more than a regulatory requirement—they’re an essential investment in safety, business continuity, and asset protection. Whether you’re protecting sensitive equipment or managing high-risk industrial operations, choosing the right system can mean the difference between containment and catastrophe.

✔️ Rapid Detection & Response – Identifies fire within seconds and activates suppression automatically, reducing damage and allowing safe evacuation.

✔️ Water-Free Alternatives – Uses gas, foam, or chemicals to protect water-sensitive areas such as data centers, archives, and control rooms.

✔️Regulatory Compliance – Meets UAE Civil Defense and NFPA standards, ensuring safety and eligibility for insurance coverage.

✔️ Business Continuity – Prevents operational shutdowns and limits downtime in high-risk industrial or commercial environments.

✔️Asset Protection – Minimizes loss of equipment, data, and irreplaceable assets through targeted, fast-acting suppression.

✔️ Versatile Applications – Suitable for diverse settings: commercial kitchens, warehouses, telecom facilities, museums, and more.

All fire suppression systems must operate within the framework of fire safety regulations in Dubai, ensuring safety and regulatory approval before commissioning.

Final Word: Why Fire Suppression is a Non-Negotiable

Investing in a reliable fire suppression system is not just a safety measure—it’s a strategic decision that protects lives, assets, and operational continuity. With a wide range of suppression agents, smart activation mechanisms, and customized applications for different environments, these systems are essential for both compliance and peace of mind.

At Daem Contracting Company, we specialize in Fire Systems Services and Solutions, including designing, installing, and maintaining fire suppression systems tailored to your facility’s specific needs.

Whether you manage a data center, industrial plant, or hospitality venue, our certified team ensures full compliance with UAE Civil Defense standards and international safety codes.

Client Questions, Expert Answers

1. Do I need Dubai Civil Defense approval before installing a fire suppression system?

Yes. All fire suppression systems in Dubai must comply with Dubai Civil Defense approval requirements to ensure safety and legal operation.

2. What is the Civil Defense Certificate and why is it important?

The Civil Defense Certificate confirms that a facility complies with all required fire safety standards. It is essential for legal operation and insurance coverage.

3. Where can I find detailed fire safety regulations in Dubai?

Detailed information on fire safety regulations applicable in Dubai is available on the fire safety regulations in Dubai page, which outlines design, installation, and maintenance requirements.

4. How do I ensure my Fire Safety System stays compliant and effective over time?

To ensure your Fire Safety System Maintenance and Inspection Contract remains fully compliant with UAE Civil Defense standards, we recommend establishing a regular maintenance schedule that includes periodic inspections, testing, and documentation. This not only guarantees uninterrupted protection but also prevents unexpected failures and secures official certification from the authorities.

M. Hussam Almahmoud

Business Owner | DAEM CONTRACTING LLC Dubai

M. Hussam Almahmoud Graduated From Aleppo University BSC in Mechanical Engineering, CEO and partner In White Eagkes Hen trd ( established in 2005 , White Eagle Transport Est 2008 , City care Fire Est 2010 , Daem Contracting Est 2014 , Abraj Wa Mabani cont Est 2016 , White eagles gen trd LTD Est 2021 in Manchester UK , Partner in ICE Elektronik Dis Ticarat limited Sirketi Istanbul turkey

Comments are closed