- hussam

Fire Pump Installation Essentials by DAEM CONTRACTING LLC

Table of Contents

Introduction: Fire safety is paramount, and mastering the intricacies of fire pump installation is key to safeguarding lives and assets. Ensuring a reliable water supply and pressure for fire protection systems is a critical aspect of commercial building design. Fire pumps play a pivotal role, providing the necessary force to guarantee adequate flow and pressure for firefighting needs. It’s vital to adhere to precise installation, testing, and maintenance protocols to ensure these systems are ready to perform flawlessly during an emergency. This article delves into the crucial aspects and industry-recommended practices for both diesel and electric fire pump installations, aiming to uphold safety standards and protect both people and property.

Sizing the Fire Pump

Choosing the right fire pump size is key for effective fire safety. It’s about finding a balance to deliver enough water at the right pressure for firefighting. We look at everything from water supply and pipe sizes to building design and what the fire systems need. Calculating the fire pump’s churn pressure is vital. This ensures the pump can handle the system’s demands and reach the farthest sprinklers or standpipes with enough pressure. Too big and it’s a waste of money; too small and it might not fight fires well. Companies like DAEM Contracting LLC use special software to pick the best pump size, making sure it’s just right for safety and efficiency.

Fire Pump Configuration Types

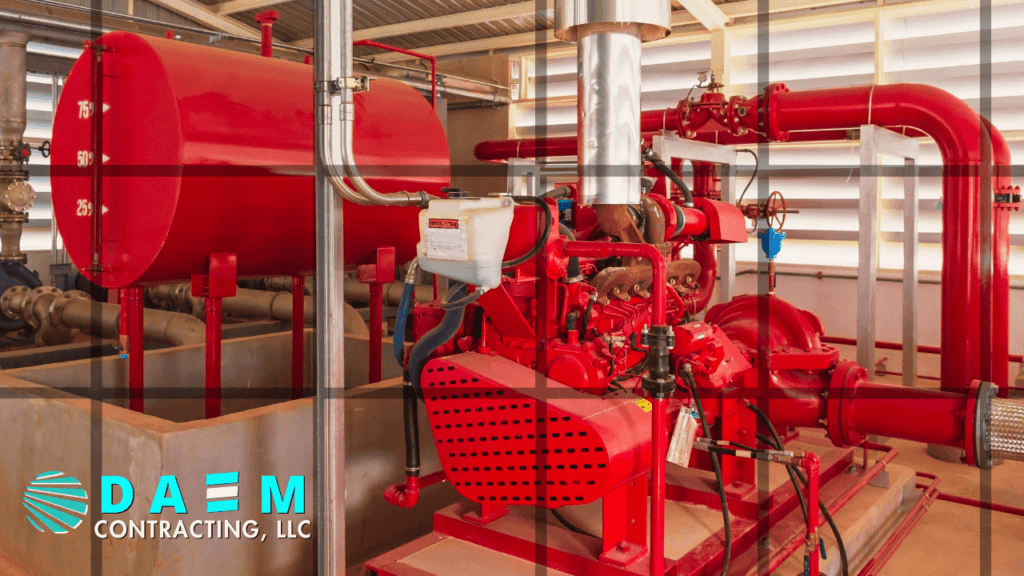

Fire pump systems come in various configurations, each designed to meet specific needs and requirements. Here are the main types:

- Single Pump Setup: This is the most straightforward configuration, involving just one pump that either runs on electricity or diesel. It’s used in smaller or less complex buildings where a single pump can provide sufficient water flow and pressure for fire suppression.

- Parallel Pump Configuration: For larger buildings or those with higher fire safety demands, multiple pumps may be installed in parallel. This setup ensures redundancy and increased capacity, as the combined effort of the pumps can deliver a higher volume of water at the required pressure. In case one pump fails, the other(s) can still operate, providing a fail-safe mechanism.

- Diesel and Electric Pump Combination: Combining diesel and electric pumps offers the advantages of both power sources. While electric pumps are efficient and easy to start, diesel pumps provide reliability in case of a power outage. This hybrid setup ensures that fire protection is maintained under various scenarios.

- Jockey Pump Addition: A jockey pump, also known as a pressure maintenance pump, is a smaller pump used to maintain pressure in the fire protection system to prevent the main pump from cycling on and off unnecessarily. This is particularly useful in preventing wear and tear on the main pump and ensuring that the system is always ready for immediate use.

- Vertical Turbine Pumps: These are used when the water source is below the pump or ground level, such as in wells or reservoirs. Vertical turbine pumps are designed to lift water to the necessary height, ensuring that adequate pressure is available for the fire protection system.

Each configuration offers different benefits and is chosen based on the specific requirements of the building or facility, including size, layout, and available water supply. DAEM Contracting LLC specializes in assessing these factors to recommend and implement the most efficient and effective fire pump configuration, ensuring compliance with safety standards and optimal performance.

Fire Pump Installation Details Guidelines

Proper installation of fire pumps is critical for the safety and efficiency of firefighting systems. Here’s a comprehensive guideline for the installation of fire pumps:

- Foundation and Mounting:

- Fire pumps should be securely mounted on concrete foundations. To minimize operational movement and vibration, it’s advisable to employ vibration isolation techniques.

- It’s essential to anchor the piping close to the floor slab for added stability.

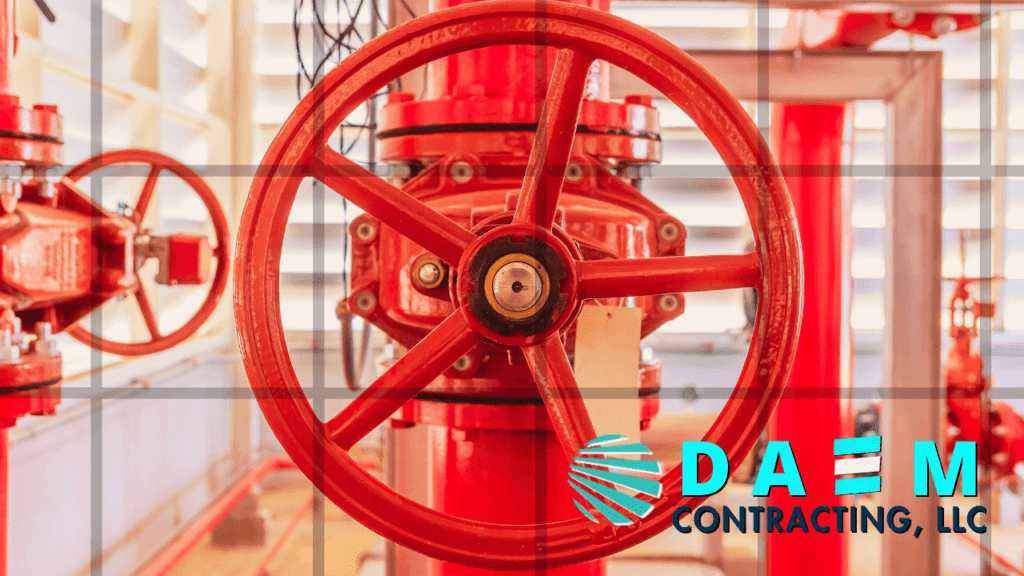

- Suction Piping:

- Suction piping should be designed for smooth flow with minimal friction losses. This typically involves the use of pipes that are easy to bend and maintain a steady flow.

- An eccentric reducer placed on the suction side can help in ensuring an unfolded flow into the fire pump’s suction flange. This setup prevents air pockets.

- Incorporate a screened strainer to filter out debris, a check valve to prevent backflow, a flow meter for monitoring, and pressure gauges for real-time pressure data.

- Discharge Piping:

- Discharge piping extends from the fire pump outlet, routing water to sprinklers, standpipes, and other fire suppression systems.

- Installation should include a discharge pressure gauge to monitor the output pressure and a check valve to prevent reverse flow.

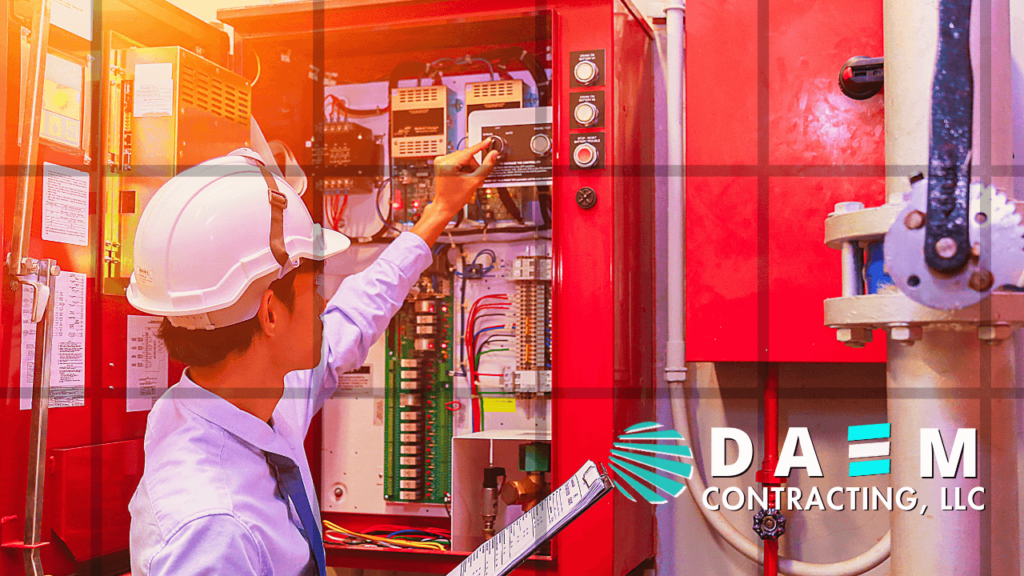

- Electrical Systems for Electric Fire Pumps:

- Electric fire pumps must be connected to shunt-trip breakers, which ensure the power is cut off if the water flow ceases, to avoid pump damage.

- Proper wiring for control panels, battery chargers, and automatic start controls is essential for the operational reliability of the pump.

- Diesel Pump Requirements:

- Diesel-driven pumps require additional setup for engine cooling, exhaust systems, fuel supply, and storage.

- It’s crucial to ensure proper ventilation and containment for fuel tanks to prevent hazards.

- Jockey Pump Integration:

- Before the main fire pumps kick in, jockey pumps are used to maintain a preset pressure in the fire protection system’s piping.

- Correctly configuring and troubleshooting jockey pumps are crucial for seamless operation between the jockey and main fire pumps.

- Environment and Accessibility:

- Ensuring adequate ventilation, lighting, drainage, and heating within the pump room is necessary to maintain an environment conducive to the equipment’s longevity.

Commissioning and Maintenance

Commissioning and Maintenance are critical phases in the lifecycle of various systems, particularly in construction and building management. These phases ensure that installed systems operate according to their designed specifications and continue to function efficiently over time. Here’s a detailed overview of both:

Commissioning

Commissioning is the process of verifying and documenting that a building’s systems and components meet the designed specifications and operational requirements. It’s a quality-oriented process for achieving, verifying, and documenting that the performance of buildings, systems, and assemblies meets defined objectives and criteria. This process begins at the project planning stage and continues through construction, acceptance, and the warranty period of the project.

Key Steps in Commissioning:

- Planning and Documentation: Establishing commissioning requirements, developing a commissioning plan, and defining performance criteria.

- Design Review: Evaluating the design’s ability to meet the building’s operational needs, identifying potential issues early.

- Installation Verification: Checking installations for compliance with design specifications and quality requirements.

- Functional Testing: Ensuring that systems operate correctly under various conditions and interact as intended.

- Training: Educating the building’s operational staff on proper system operation and maintenance.

- Documentation and Handover: Compiling and delivering a commissioning report that includes all test results, issues found and resolved, and operation manuals for future reference.

Maintenance

Maintenance involves the routine and corrective activities necessary to keep building systems operating efficiently. It’s aimed at extending the lifespan of equipment, reducing system downtime, and ensuring the safety and comfort of building occupants.

Types of Maintenance:

- Preventive Maintenance: Scheduled tasks to prevent equipment failure before it occurs, based on manufacturer recommendations or past experience.

- Corrective Maintenance: Repairing or replacing equipment after a failure has occurred to restore it to operational condition.

- Predictive Maintenance: Using data analysis tools and sensors to monitor equipment condition in real-time, predicting when maintenance should be performed before failures happen.

Benefits of Proper Maintenance:

- Extended equipment lifespan

- Reduced energy consumption

- Improved system reliability and efficiency

- Lower total cost of ownership

- Enhanced occupant comfort and safety

Integration with Commissioning

The commissioning process provides a solid foundation for effective maintenance. By thoroughly testing systems and ensuring they operate as intended, commissioning helps identify and correct issues early, reducing the need for corrective maintenance later. The documentation and training provided during commissioning equip maintenance teams with valuable information on system design, operation, and troubleshooting.

Maintaining Your Fire Pump

Maintaining your fire pump is crucial for ensuring it remains operational and reliable in emergencies. Regular maintenance helps to prevent failures, extend the pump’s life, and ensure it performs effectively when needed. Here’s a guide tailored for DAEM CONTRACTING LLC, reflecting our commitment to excellence in fire safety systems:

Weekly and Monthly Tests

- Weekly Checks: Test fire pumps weekly to verify the automatic start operation is functioning correctly.

- Monthly Diesel Engine Tests: Conduct a minimum of 30 minutes of pumping under load to maintain diesel engine efficiency.

Monthly Visual Inspections

- Inspect fire pump systems visually for leaks or mechanical issues.

- Ensure there is adequate fuel for diesel pumps and batteries are charged.

Lubrication and Maintenance

- Follow the manufacturer’s lubrication schedule for fire pump bearings and diesel engine parts.

- Replace air filters, belts, hoses, water seals, and other accessories as directed by the manufacturer.

- Keep a stock of spare parts for critical components.

Adjustment and Cleaning

- Tighten pump packing glands as needed to prevent leaks, with re-packing typically required annually.

- Clean and adjust diesel engine components such as electrodes, sensors, and injectors based on operating hours or as recommended.

Additional Annual Checks

- Inspect fuel tanks and piping for corrosion or leaks annually.

- Drain water and sediment from diesel fuel tanks regularly.

- Test relief valves annually, ensuring drain lines discharge safely.

- Service batteries yearly, checking for clean terminals and proper charge levels.

- Conduct an annual flow test under load to re-verify pump performance against original acceptance test results.

Corrosion Control

- Repaint pumps, engines, and piping as necessary to prevent corrosion.

By adhering to these maintenance guidelines, DAEM CONTRACTING LLC ensures the reliability and efficiency of fire pumps, safeguarding properties and lives against fire emergencies. Our proactive approach to fire safety reflects our commitment to delivering superior service and peace of mind to our clients.

Align Your Fire Pump Installation with Local Code Standards

To ensure your fire pump installation meets local codes and requirements, follow these critical steps:

- Stay Updated on Codes: Regularly review the latest editions of NFPA standards (e.g., NFPA 20 for fire pumps) and all applicable state and local fire codes. These codes set the minimum requirements for pump sizing, room design, clearances, and more, providing a baseline for compliance.

- Engage Qualified Professionals: Work with a qualified fire protection engineer or contractor familiar with the local codes and permitting process. Their expertise can guide the design process, ensuring it meets all regulatory standards. Always verify qualifications and references before hiring.

- Detailed Plan Submission: Submit comprehensive plans for your fire pump system to the local fire marshal’s office, building department, or other relevant authorities for review and approval. These plans should include pump curves, room layouts, piping schematics, and any other pertinent details to ensure thorough evaluation.

- Schedule Inspections: Arrange for both intermediate and final inspections by local officials at crucial installation stages. This proactive approach allows for the identification and rectification of any compliance issues early in the process, ensuring a smoother final approval.

- Perform Comprehensive Testing: After installation, ensure the installing company conducts thorough testing according to NFPA standards and local requirements. Tests should include flow tests, pressure readings, and automatic start verifications, with all results documented.

- Secure Operating Permits: Once your fire pump installation is complete and tested, obtain any necessary operating permits from local fire departments or regulatory agencies. These permits are often required for the system to be officially recognized and operational.

- Maintain Detailed Records: Keep detailed records of all installation details, testing results, inspections, maintenance logs, and manuals on-site. Having this information readily available supports compliance and facilitates any future inspections or maintenance activities.

- Implement Code-Compliant Signage: Ensure all required signage is visible and properly displayed, including fire pump room identification, equipment labels, warning signs, and connection markings. This signage is crucial for both compliance and safety.

Fire Pump Room Design

The document outlines specific requirements for various aspects of fire safety and emergency systems, including the design and installation of fire pump rooms, which are critical components for ensuring adequate water supply for firefighting efforts in buildings. Here are the key points relevant to the design of fire pump rooms based on the provided document:

- Location and Accessibility: The pump room should be easily accessible for maintenance and emergency operations. It must be located in a place that ensures the pumps are not susceptible to freezing temperatures unless adequate precautions are taken.

- Size and Layout: The room should be spacious enough to accommodate the fire pump assembly, including pumps, drivers, controllers, and other associated equipment, with sufficient space around them for easy access and maintenance.

- Fire Protection: The pump room itself requires protection against fire, often including fire-rated walls and doors. This is to ensure that the fire pump system remains operational even if a fire occurs within the building.

- Ventilation: Adequate ventilation must be provided to handle the heat generated by the pump operation and to ensure the safety of personnel working within the space.

- Electrical Safety: Electrical installations in the pump room must comply with safety standards to prevent any risk of fire or electrocution. This includes proper grounding, circuit protection, and safe wiring practices.

- Water Supply: The pump room design must include provisions for an adequate and reliable water supply. This involves connections to water sources, such as municipal water lines or storage tanks, with safeguards to prevent backflow or contamination.

- Control Systems: Fire pump rooms are equipped with control systems to start and stop the pump automatically in response to fire alarm signals or water pressure changes. These controls must be accessible and clearly labeled.

- Alarms and Indicators: Alarm systems are required to monitor the status of the fire pump operation. This includes alarms for situations like pump activation, high water temperature, or electrical faults.

- Signage and Marking: Proper signage must be provided in and around the pump room to indicate the presence of fire protection equipment, electrical hazards, and the flow direction of water in the piping.

- Maintenance Access: The design should facilitate easy access to all components for routine inspections, testing, and maintenance. This may include provisions for removing and replacing parts of the pump assembly.

- Compliance with Standards: The entire design and installation of the fire pump room must comply with relevant local and international standards and regulations. This ensures the system’s reliability and effectiveness in case of a fire.

- Documentation: Comprehensive documentation, including design drawings, specifications, and operating procedures, should be maintained for the fire pump system. This information is crucial for ongoing maintenance, inspections, and any future modifications to the system.

These points highlight the critical considerations in designing a fire pump room to ensure it functions effectively as part of a building’s fire protection system.

DAEM CONTRACTING LLC Fire Approval Service

DAEM CONTRACTING LLC’s fire approval service plays a pivotal role in ensuring construction projects comply with the highest standards of fire safety, securing the necessary endorsements from relevant authorities. This comprehensive service includes:

- Preparation and Submission of Documents: Crafting and organizing all required documents, drawings, and plans for submission to civil defense and other regulatory bodies.

- Liaison with Local Authorities: Acting as the intermediary between the project and the local fire department or civil defense authority to ensure smooth communication and clear understanding of requirements.

- Compliance Checks: Reviewing project plans against local and international fire safety standards (e.g., NFPA) to guarantee compliance before submission.

- Detailed Planning and Design Review: Providing expert analysis of fire protection system designs, including fire alarms, sprinkler systems, and emergency exit layouts, to ensure they meet regulatory standards and project needs.

- On-Site Inspections: Coordinating and facilitating on-site inspections by authorities to verify the implementation of fire safety measures according to approved plans.

- Correction of Discrepancies: Assisting in the modification of plans or systems as needed to address any issues raised during the approval process or inspections.

- Final Approval and Certification: Securing the final fire safety approval and necessary certifications that affirm the project’s compliance with all fire safety regulations.

- Post-Approval Support: Offering guidance and support for maintaining compliance throughout the project lifecycle, including any necessary re-inspections or documentation updates.

DAEM CONTRACTING LLC ensures that every aspect of your project’s fire safety measures is meticulously managed, from initial design to final approval, streamlining the process while upholding the utmost standards of safety and compliance.

Additional Fire Pump Installation Details

When installing fire pumps, DAEM CONTRACTING LLC emphasizes the importance of meticulous attention to specific technical details that enhance the system’s efficiency, reliability, and compliance with safety standards. Below are crucial additional installation details to consider:

- Net Positive Suction Head (NPSH): It’s vital to ensure adequate NPSH to prevent pump cavitation. This involves precise calculations based on design flow and static lift conditions, safeguarding the pump’s operational integrity.

- Pump Room Elevation: For systems where pumps take suction from ground-level tanks, the pump room should be positioned at least 18 inches lower. This design consideration is critical for maintaining proper suction conditions and pump efficiency.

- Impeller Sizing: Size impellers to produce 150% of the rated pump capacity at 65% of the total head. This specification accounts for potential wear and tear over time, ensuring the pump maintains adequate capacity throughout its service life.

- Vibration Isolation: To prevent the transmission of equipment vibration to the building structure, which could lead to damage or noise issues, use flexible pipe couplings and isolation pads. This also contributes to the longevity of the pump and associated piping.

- Pressure Maintenance (Jockey) Pumps: Include jockey pumps sized for a minimum of 10% of the main pump rated capacity. These pumps play a crucial role in maintaining system pressure, reducing the need for the main pump to cycle on and off for minor pressure fluctuations.

- Wiring and Conduit: Arrange all wiring in protective conduit, enhancing safety and reducing the risk of damage. It’s particularly important for emergency power supply wiring to be separated from normal building circuits to ensure the fire pump system remains operational during a power outage.

Conclusion

In conclusion, DAEM CONTRACTING LLC’s comprehensive approach to fire safety and approval services underscores the critical importance of adhering to fire safety standards and regulations in construction projects. By meticulously managing every step of the fire approval process, from document preparation to final certification, DAEM CONTRACTING LLC ensures that projects not only meet but exceed the required fire safety measures. This dedication to excellence and safety reflects DAEM CONTRACTING LLC’s commitment to protecting lives and properties, while also streamlining the approval process for our clients. Our expert team, equipped with the knowledge of local and international fire safety codes, provides unparalleled support and guidance, ensuring your project progresses smoothly and efficiently towards completion with full compliance. Trust DAEM CONTRACTING LLC to safeguard your project’s success and integrity through our specialized fire approval services.

For further information, consultation, or services regarding fire pump systems, DAEM CONTRACTING LLC invites you to reach out through the following channels:

Website: daemuae.com

Office Address: 20 18 St., RAS AL KHOR Industrial Area, Dubai, UAE

Phone Number: +971 50 884 9955

Email: info@daemuae.com

DAEM CONTRACTING LLC is committed to excellence in fire safety solutions, ensuring your projects not only meet but surpass the necessary fire safety standards. Our team of experts is ready to assist you with comprehensive support, from initial planning to final commissioning and maintenance. Contact us today to learn how we can enhance the safety and efficiency of your fire pump installations.

Comments are closed